Views: 335

在国际采购的课堂上教授分享了一个案例供学生们讨论,据说这个案例在目前国内的采购领域相当普遍,有达七成的公司面临类似的问题或者说困境。

In a lesson on International Purchasing, the professor provided a case study for students to discuss. It is said that currently this case study is typical in the field of purchasing in China, with about 70% companies faced with similar problems or dilemmas.

因为案例只提供了纸质版文件,没有电子档,因此只有委屈大家看图了。

There is only a printed version of the case study and no electronic one, so you have to look at a picture.

在笔者看来,这是一个典型的执行传统采购的公司里的采购的做法,介于小采购与大采购之间,因为小采购是关注于订单的执行的,而大采购关注于关系的建立和优化,JIMMY的日常工作中还在扮演救火与解决问题的角色,虽然每天很忙碌,但是基本上都是在解决短期的供应问题,还没有将中长期要解决的流程和制度问题放上议程或者说开始实施。

在笔者看来,这是一个典型的执行传统采购的公司里的采购的做法,介于小采购与大采购之间,因为小采购是关注于订单的执行的,而大采购关注于关系的建立和优化,JIMMY的日常工作中还在扮演救火与解决问题的角色,虽然每天很忙碌,但是基本上都是在解决短期的供应问题,还没有将中长期要解决的流程和制度问题放上议程或者说开始实施。

As far as I am concerned, this is a traditional practice typically adopted by a purchasing company, falling in between small purchasing and big purchasing. The former focuses on order execution while the latter values relationship establishment and optimization. JIMMY also plays an important role in rescuing emergency and solving problems. Busy as he is every day, most of the issues that he deals with are short-term supplying problems while mid-and-long-term issues of process and regulation remain to be put on the agenda and into effect.

JIMMY 在很多公司都很常见,在一些公司老板会看到JIMMY的不足,以及要改进的地方,但是在相当多的公司内JIMMY也许还是公司的红人,要人,老板的左膀右臂,遇到问题其他的部门都会为他让路,全力配合他去解决交货与生产短缺,原因在于他还能解决一些问题,以致于给人一种错觉好像公司缺他不可,从而更让他反而有一种自豪感,不思进取。就如同品质部在很多公司画很多精力在解决“纠正措施”的问题,疲于应付客户的投诉,没有解决“预防措施”的问题,反而让老板觉得质量部解决客户的投诉由“责任”变为了“贡献”,最终成为了“增值”的活动,的确有效的解决客户的投诉和诉求能增加客户的满意度,但是最终客户要的效果是没有投诉,事前有效的预防和管控,而不是事后的纠正。

JIMMY is a common character that exists in many companies. Some bosses may recognize the disadvantages and shortcomings of JIMMY that calls for improvement. But chances are larger that JIMMY is a favorite by bosses in most places. Since he is capable to solve some tricky problems, other sectors will make way for him and spare no effort to assist him to solve the problems of delivery and production shortage. There is thus an illusion that he is indispensible to the company, which gives rise to a sense of pride in him and may foster his unenterprising spirit. It is similar to the case of the quality sectors in many companies. They are busy addressing customers’ complaints, spending a lot of time and efforts on rectification rather than precaution, which leaves a false impression on the boss that by responding to customers’ complaints, the quality sector is creating value and making contribution to the company rather than fulfill its commitment. It is true that customers can obtain satisfaction when having their complaints settled and appeals met. But what they really need is no complaints: effective precaution and control beforehand instead of rectification afterwards.

经过同学们15分钟集思广益,教授的提示及引导,大体形成了如下的解决思路,不排除有其他观点的遗漏。

After a 15 minutes’ brainstorming by students under the guidance of the professor, a general solution came into being with possible omission of ideas that are not covered.

1.采购经理的能力有待加强Enhancing the purchasing manager's ability.

1.1 采购经理的时间管理和任务优先性管理需要加强The purchasing manager's time management and task prioritization management needs improving.

整体来讲JIMMY应该能意识到很多事情要做,但是如何更好的分配时间和下属资源,以及自身的优先性管理,这是JIMMY需要思考的问题,毕竟长期救火JIMMY是不会有时间来思考更长远的问题,而接到电话就立马处理的办事风格更让人怀疑其管理的计划性。“供应链管理 – 实践者的角度”作者 刘宝红曾经比如传统采购向战略采购如同给奔驰的汽车更换车轮,是一个相当挑战的任务。

Generally speaking, JIMMY is able to be aware that there is a lot of work to do. But what calls for contemplation for him is how to allocate time and staff resource more effectively and realize self prioritization management. After all, always being hooked on emergencies would spare him no time for foresight consideration, and people would doubt his management planning ability if he kept the working manner of taking immediate action upon phone calls. Baohong Liu, the author of Supply Chain Management—from Practitioners' Perspective, once compared the shift to strategic purchasing from traditional purchasing to the replacement of wheels for Benz, a rather challenging task.

1.2 对任务的跟踪能力The ability of task tracing

案例中JIMMY提供了样品就等待设计部给答复或者说没得到答复就默认为认可的做法不为可取,尽管在实际的生活中颇为常见。要知道管理的其中一项技能是跟踪任务的实施,而不是仅发号施令,等待结果的发生。

Common as it may be in daily life, it is not advisable that JIMMY waits along for reply of the design sector after the sample is submitted, or acquiesces in its feasibility before any reply. It should be clear that one skill in management is to trace the implementation process of tasks, rather than just give orders and wait for outcomes.

1.3 采购经理的跨部门沟通的能力不足The purchasing manager's ability of cross-sector communication is deficient.

这体现在在多个利益相关体中JIMMY总是扮演老好人,帮大家和公司解决问题,以及由其他部门造成的问题,比如案例中销售没经过对公司交期能力的了解就贸然签单,设计部随意指定供应商就让JIMMY去砍价,JIMMY也欣然接招,等等。

This can be seen in many stakeholders. JIMMY always plays the role of a kind man, not willing to offend anyone. He helps to the problem caused by others, the company and other sectors. Examples in the case study include the salesmen sealing a deal without any idea about the company's delivery capacity and JIMMY getting to bargain with a supplier randomly designated by the design sector.

其次JIMMY没有对垮部门的流程定义出来,流程的不足造成JIMMY成为大家的众矢之的,要知道对于可怜之人必有可恨之处,弱势部门保护自己的强有力武器是流程。一个国家如何让老百姓有感觉自己是当家做主,从东方的民主自由到西方的自由民主,法律功不可没,于公司而言,流程就如同国家的法律。

Besides, JIMMY does not make up a well-defined cross-sector communication process, the weakness of which has pushed JIMMY to the target of public criticism. The process is a powerful weapon for the weak to protect themselves. Whether in eastern or western democracies, the law plays an important role in guaranteeing people's rights to participate in the country's politics. The process to a company is what the law to a country.

再次JIMMY也需要完善垮部门的沟通机制,采购的中心和基本职能是保障供应,尽管物料短缺好像罪魁祸首不是采购,但是采购需要主导解决方案,就像产品缺陷是设计失误或者制造缺陷,不是品质部造成的,但是终归由品质部来统筹解决一样。在案例中建议JIMMY需要固定周期的垮部门会议,来及时了解波动的客户的需求,动态的仓储状况,以及随时波动的生产计划和品质表现。

What's more, the cross-sector communicative mechanism needs to be optimized. Although the chief culprit for material shortage should not go to the purchasing sector, it is supposed to carry out and dominate a solution since the core and basic function of purchasing is to guarantee supply. Similarly, products are caused in designing or production process rather than by the quality sector, but it eventually calls for the quality sector to coordinate and solve the problem.In the case study, JIMMY should hold periodic cross-sector meetings so as to have an immediate comprehension of changeable customer demands, dynamic storage situation and fluctuant production planning and quality performance.

2.对于计划与预测的管控要加强Enhancing the control of planning and forecasting.

JIMMY需要和计划,业务交清底牌 – 哪些非标物料的交期是多久,需要提前准备,防止销售贸然承诺客户。对于销售提供的预测数据是需要画个问号先,并不是说销售故意提供假的预测数据,原因在于市场变幻莫测,没准销售从客户那里收到的数据还依赖于上游二级乃至三级客户的准确性,这就是供应链环节的所谓“牛鞭效应”。客户为了保障给其客户的供应,他们可能会将实际1000的需求量扩大为1500,而公司销售收到1500的要求后为了不失信于客户,则有可能会再放大到2000。刘宝红老师的观点是决定由数据开始,判断结束,总比全程拍脑袋的准确性要高,要知道战略层面在年初拍脑袋定下的销售额预测可能还比较准确,生产,采购的年度预测也还行,但是落实在战术层面上每周的预测就可能差之千里了。在此同学们给出的一个思路是计划与预测需要结合静态与动态两块数据,静态指实际已经发生的现有信息,这些包括历史的销售,采购数据,现有的自身仓库和供应商端的库存数据等,动态的则是销售的预测数据,供应商提供的前置期等。两者结合会更接近实际的需求,毕竟想要获得的信息的准确性高低与资源的投入多少也有一定关系。

JIMMY should have an immediate and effective communication with the planning and sales departments and tell them the real capability of suppliers : Which are non-standard materials, what are their deliveries and when should they be prepared in advance in case the salesman rashly accepts an order from customers. The forecasting data provided by salesmen should be put under scrutiny first. It does not mean that salesmen will deliberately provide false forecasting data. But since the market is changeable, it is possible that the accuracy of the data salesmen obtained from customers should depend on the upstream secondary and tertiary customers. This is referred to as the Bullwhip Effect in supply chain. When an upstream customer wants to ensure supply to a downstream customer, it may play an increased order with a supply company. For example, it may enlarge the actual demand of 1000 in amount into 1500. When the supplier receives an order of 1500, however, it may increases the order to an amount of 2000 so as to ensure that the order can be fulfilled on time. According to Professor Liu Baohong, a decision should begin with data and end with judgment rather than be based on groundless intuition. The forecast for sales, production and purchasing casually determined by the strategy layer may be relatively accurate at the beginning of a year, but great discrepancy will emerge in the week forecasting on the tactics layer. Thus the students put up with an idea that both static and dynamic data should be adopted in the process of planning and forecasting. Static data refers to the available data drew from events that already happened, including historical sales data, purchasing data, current stock information from the warehouse and the suppliers. Dynamic data refers to forecasting data of sales and the lead time proposed by supplier. A combination of the two makes it closer to the actual demand. After all, the accuracy of the information is, to some extent related to the input of resources.

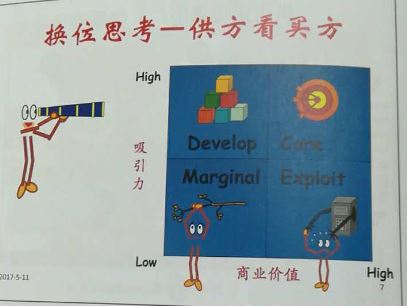

3.供应商感知模型的运用Using the Supplier Perception Model

与此同时鉴于JIMMY公司的业绩增长保持在两位数,JIMMY也需要与供应商保持良好的信息沟通和共享,了解清楚供应商的供应能力和意愿,供应商愿意同公司一起成长而配合公司增加设备,人力资源等保障供应吗?在供应商的眼中,他们又是如何看待JIMMY公司的,这就涉及到供应商感知模型的运用。并不是说很有商业价值的客户就一定具有吸引力而成为核心客户的。正所谓门当户对,是指两者都你情我愿才会产生长久的合作。

Meanwhile, in view that JIMMY’s company enjoys a double-digit growth, JIIMMY shall keep a good communication with the suppliers in information exchanging and sharing. He should also have a clear understanding of the suppliers’ supplying competence and willingness. Whether they are willing to increase facilities, human resources and so on to ensure adequate supply to the company? How is JIMMY’s company like in the mind of the suppliers? All these questions refer to the use of the supplier perception model. Customers of great commercial value are not meant to be attractive and will therefore become the core customers. A long cooperation calls for two parties that have the willingness to work with each other in order to be well-matched.

4.对零部件的重要性划分Rating Parts by Importance

4.对零部件的重要性划分Rating Parts by Importance

JIMMY不能眉毛胡子一把抓,需要分清哪些是关键物料,哪些是常规采购物料,做到有的放矢。具体可以参考供应定位模型(瓶颈,日常,关键,杠杆)。此外供应商也显得有些单一,同一品类的关键物料应该需要做足准备工作,确保风险的最小化。

JIMMY should not attend to big and small matters all at once. But rather, he should tell apart key materials and normal materials so as to have a definite object in view. The supply positioning model can be referred to for more specific information (bottleneck, routine, critical and leverage). Besides, the suppliers appear to be unitary. An adequate stock of key materials of the same class should be prepared before hand in order to minimize risks.

5. 对风险的管理思路Ideas for Risk management

基于对零部件的重要性划分,也有人提出了JIMMY对待断货的风险管控需要借鉴风险管理模型,比如对企业影响大,发生机会高的需要优先关注,将对企业的影响与发生的概率作为两个纵向交错的轴来进行管理。

Apart from rating accessories by importance, some also note that JIMMY should learn from the risk management model for the risk management and control of stock shortage. For example, accessories that easily encounter shortage and have great influence on the company should be given prior attention, described in a coordinate axis with Influence on the company and probability to happen as the two axes.

6.供应商的选择流程失效Failure in the Supplier Selection Process

供应商选择引进的程序需要定义出来,以确保采购提前参与进来,而不是在设计部定好型,选好供应商后仅仅只是操作后续的日常采购订单。供应商的选择流程需要考虑分为几个阶段以及每个阶段下该做的事情和由哪个部门主导,目的在于确保各个相应部门都有在前期参与,第一保证利益的均衡,第二保证需求的满足,第三平衡效率与风险。在案例中先批准样品,再在即将下订单时去找供应商谈价格明显是前后颠倒,要知道供应商临时切换的时间成本和机会成本是非常高的,正常的顺序应该是先定标准和要求来报价,其次再确认样品。

The process of supplier selection and bringing in should be clearly defined so that the purchaser can start his work in advance rather than simple fulfill daily purchasing orders that come after the decision on goods specification and suppliers by the design sector. In determining the supplier selection process, a company need to consider how many stages the process comprises, what should be done on each stage and each stage should be led by which sector in order to make sure that the relevant sector can undertake their work in time. First, make sure that benefits are balanced; second, make sure that demands are met; third, balance between efficiency and risks. In the case study, the company reversed the sequence by first deciding on the sample and then bargaining with the supplier when the order was ready to be played. We should know that there is a high time and opportunity cost for switching suppliers. The normal sequence is to decide on the specifications and quote and then decide on the sample.

第二,按照常规的供应商选择流程,应该是所有的采购订单发往合格供应商,而合格供应商是需要建立清单进行严格管控的,进入合格供应商清单的供应商前期需要经过一系列的评估,这样JIMMY面临的一些问题可以在前期过滤掉了,想必JIMMY可能没有意识到这点。

Besides, according to the conventional supplier selection process, all the purchasing orders are sent to qualified suppliers which are named in a list by the company for strict management and control. A series of assessments are conducted before a supplier can be listed as a qualified supplier. In this way, some problems encountered by JIMMY might have been filtered in advance. Perhaps he was not aware of this fact.

7. ERP系统的运用和升级Using and Upgrading the ERP System

大部分同学都意识到了ERP的运用给公司带来的便捷与效率,但在实际工作中要说服一个不实际操作系统的老板来讲,的确不是易事。一个好的管理系统其实已经将公司的流程嵌入到了系统内部,就像大家觉得电脑的速度是越来越快,但是体积是越来越小,从操作界面来讲是越来越方便,大家并不会看到各种0/1的算法,但实际上它又确是在电脑的内部计算和处理中实际发生的一样。一方面尽量采用投资回报的计算方式来证明ERP系统的商业价值,另外一方面也需要JIMMY将公司的现状 – 变革 – 未来 里程图展现给老板,让老板看到上一个好的ERP系统如何给未来起到一个建地基,铺路的效果。有同学结合贴身感受推荐澳洲ERP系统PRIORITY (http://www.priorityerp.com/),但是据说价值也不菲,需要上百万美金,不知是真是假。

A majority of students have realized the adoption of the ERP System will bring convenience and efficiency to the company. But it is not an easy job to persuade a boss who has not used the system into adopting it. As a matter of fact, a qualified management system will have had the corporate process embedded into itself. It is like a computer, which gets faster in speed but smaller in size and whose operating interface becomes more and more convenient. Various algorithms are not visible to us, but they are actually worked on and processed in a computer. On one hand, the calculation of ROI should be put into use to access the commercial value of the ERP System. On the other, it requires that JIMMY present to the boss a situation-revolution-future mileage chart, with which the boss is able to see how a qualified ERP System can lay the foundations and pave the road for the future. Some students recommend PRIORITY (http://www.priorityerp.com/), an Australian ERP System, supported by their own experiences. It is said to be expensive, costing millions of dollars. I am not sure whether it is true or not.

8. 扩展A Real-Life Example

由于案例给出的信息并不是十分完整,有同学分享一个一个他们公司实际的操作手法,将客户特殊的需求与价格相关联。具体的做法是如果常规的交期是一个月,但是如果客户临时下订单时要求的交期是15天,公司会答应新的交期,但是销售价格大幅上涨或者付款条件变为更加苛刻,一方面实际情况是可能整个供应链都需要加班或者通过额外的资源调配来完成这个需求,另外一方面也为增加产品的利润率。但是有从事销售领域的同学立即指出这个方法的一大弊病就是很容易流失客户,因为客户也会在市场上进行综合比较,一旦发现有更加具有竞争力的供应商可能会立马切换过去。可能在实际的例子中这种实践主要适用于少量多样及及卖方市场的产品。

Due to the fact that the information provided by the case study is not comprehensive enough, some students have provided an actual practice in their company. That is, associate customers’ special requirements with prices. If a customer plays a special order with a delivery time of 15 days while the conventional delivery of the item is, say, one month, the company can accept the new delivery on condition that the price be largely increased or the terms of payment be stricter. On one hand, the whole supply chain has to meet the requirement by working overtime or through extra resource allocation. On the other, the product profit margin may be increased. But some students who work in the sales domain note immediately that one big drawback of this practice is that it easily drains away its customers for customers will make comparisons in the market and once they find more competent supplies to which they will turn. Perhaps such practice is only suitable for small-volume large-variety products or products with more demand than supply.

尽管讨论来自于课堂,很多的参与讨论的同学并非来自于采购领域,但是正是因为所从事的工作的不同而站在不同的视角去看待同一个问题,给出一些建议,也许会更加切合实际吧。

Although it is a discussion in class and many students in the discussion are not professionals in purchasing, some suggestions that are proposed by them may be much more practical since they work in different fields and thus can view the same question from different perspectives.

SPECIAL ACKNOWLEDGE GIVEN TO MS.Wang Qian (Claire) FOR HER CONTRIBUTIONS OVER THE TRANSLATION.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023