Views: 988

体育锻炼三个月,坚持做仰卧起坐,腰围从36码降到33码,自身感觉效果良好。回想起以往的购买衣服的经历,不经觉得好笑。人到中年容易发福,无能男人女人都是如此,也不分国籍限制。在没有加强锻炼之前,裤子的大小是随腰围的大小而自由增大的。裤子是越买越大,从32码到33码,33码不够穿再买34码,直到一路飙升到36码,其实在从32码到36码的过程当中,自己是没有察觉的,也看不到太多的变化,直到去体检发现BIM指数超标,才会意识到问题的严重性。当然经过锻炼,控制饮食,改善作息规律,将腰围控制下来之后,反过来才会发现这当中的好处。这时才发现裤子的大小是可以被控制的,这样大腰围的多余裤子就可以捐出去了,减少了库存和“不良”浪费.

It has been three months since I took the physical exercise and insisted on sit-up exercises. Consequently, my waistline size declined from 36 to 33, and I feel good about myself. When recollecting the past experiences on purchasing clothes, I just cannot help myself but to feel funny. It is quite easy for middle-aged people to get fat, regardless of their nationality or gender. Before I took more exercise, the size of their trousers increased freely with their waistline—the trousers I bought become bigger and bigger, from 32 to 33, then 33 to 34 since 33 is not enough. Finally, the size reaches 36. In fact, I did not notice too much change from 32 to 36, nor did I realize the seriousness of the problem until I found my BIM exceed the standard when taking the physical examination. Definitely, not until I took exercises, controlled my diet and improved my daily schedule did I found the advantages among it in turn: the size of the trousers can be controlled. Thus, the superfluous trousers with big waist size can be donated, which will reduce the inventory and “undesirable” waste.

这不禁让我想起了工厂的品质控制,如果没有控制,所生产的产品的公差会越做越大。精度上不去,质量就上不去,公差不会一天之内放大,因而也看不到每天一点点公差放大所带来的负面影响,直至最后产品产生质量问题,遭到投诉,被市场所淘汰,客户丢失,才会意识到问题的严重性。如同温水煮青蛙,随着温度的慢慢上升,青蛙已经失去了对温度缓慢变化的感应能力,直至最后被沸腾的水煮熟掉。与温水煮青蛙不同的是待企业快垮掉之时往往这个时候问题已经变得错综复杂,其实也很难追究到底是什么问题造成如此的后果。就如同肥胖,你很难说,单纯是因为年龄的增长或者单纯是因为饮食的不规律,又或者单纯仅仅是人种的区别,多重因素交织在一起,但世界上每个国家的一个共识就是控制体重和腰围其中一个不可或缺的环节就是加强锻炼。就像摩托诺拉践行并推动了六西格玛管理方法的大力发展,但最终还是业绩惨淡卖掉了手机事业,并不能说六西格玛方法不对,而是其他的产品定位,产品设计,市场战略等多重原因交织造成的,相反六西格玛管理在每个公司发展的任何阶段都可以发挥积极的作用。

It suddenly reminds me of the quality control of the factory. Without control, the tolerance of the product will become bigger and bigger. The quality cannot be enhanced if the accuracy cannot be improved. Since the tolerance cannot be widen within a single day, the negative impact brought by enlarged little tolerance every day will not be noticed. Not until the product was involved in quality problem, complained by customers and abandoned by the market and clients did they realize the seriousness of the problem. It is quite similar to boiling a frog in warm water: as the temperature of water increases gradually, the frog loses its ability to be aware of the changes in temperature until they get boiled thoroughly by boiling water. However, what seems to be different from boiling a frog is that when the enterprise is about to collapse, the problem has already become considerably complicated. In fact, it is quite difficult to figure out the problem which results in such outcome. Likewise, it is hard to say that obesity is caused by the single factor such as increasing age or irregular diet, or simply caused by differences in human races, or combination of multiple factors. Nevertheless, the every country in the world has reached a consensus that one of the indispensible stages for controlling the weight and waist sizes lies in intensive exercises. Just as Motorola that conducted and promoted the six sigma management method yet sold its mobile division with dismal achievement, it is not the six sigma method but other multiple factors like product position, product design or marketing strategy mixing with each other that gives rise to this outcome— conversely, six sigma management method is able to generate positive effect at any stage of the company development.

品质和品牌是紧紧关联的,一个好的品牌的塑造需要几代人的努力,当中没有一个好的品质是很难支撑的。曾经去看过国内最大的陶瓷卫浴企业,也算是一个家族企业,品牌也相当知名,参与国内陶瓷标准的撰写。子女各分一个品牌单独经营,曾经有人发现东南亚的市场对品质要求不高,但是市场处于爆发期,因而提出可不可以另设一个品牌走低端线路,这一想法最终被掌门人所否决了。其中一个原因就是一旦在同一个集团公司内同时生产高档和低档的产品,你很难给自上层管理人员,经中层管理人员,到普通员工一个清晰的概念和定位,业务人员同样基于业绩的驱使会在推广产品时这么宣传:“这个品牌和XX品牌来自于同一个领导团队”。员工很难今天做高端产品,明天改做低端产品,即便你是在不同的产线,不同的分公司生产。如今日本质量和德国质量已经代表了来自于这两个国家的产品就是高档货,但是提及中国质量在国际上的影响,尽管中国已经有不少的大品牌,知名产品售往全球,但因为一些低端产品的影响,仍然给大多数国家的消费者的印象是“中低端产品制造国”。人民习惯于贴标签,来自北京的都是当官的,来自上海的都是小资的,来自广东的都是老板,这就是品牌给一个城市的影响。走下坡路容易走上坡路难,企业要进步,就得要上升,而不是下降,无论是销售额还是管理水准,或者是质量要求。

Quality is closely related to brand. Establishing a good brand requires efforts from several generations. Without good quality, the brand cannot survive. I once visited the biggest ceramic sanitary enterprise which possesses high brand-awareness and even engages in setting up the ceramic standards in China. As it belongs to a family business, each child of the president was assigned a brand and operated them individually. Once someone found that the South-east Asian market required less on quality while its market was booming, thus he asked whether they can establish another brand that focus on low-end market. This idea was rejected by the president, and the one of the reasons is that it will be difficult to deliver a clear concept and positioning from upper-level leaderships to middle managers and then to general staffs if producing both high-end and low-end product simultaneously in a group company. Under the motivation of performance, sales will introduce , this product and those well-known brands come under same leadership team” when promoting products. It is relatively hard for staff to focus on high-end products today while emphasizing on low-end products tomorrow, despite different product line or different branches. Nowadays Japanese quality as well as German quality can indicate that products from these two countries are of high standard, yet speaking of the international influence exerted by Chinese quality, although China has owned numerous big brands, consumers from most of the countries still tend to label China as “the country of low to middle end products”. People are accustomed to labeling people: people from Beijing are all officials, people from Shanghai are all petty bourgeois, while people from Guangdong are all bosses. This is the influence from brand on cities. It is easy to go downstairs yet hard to go upstairs, If an enterprise want to make progress, it should rise rather than decline, whether it is the sales volume, management standard or quality requirement.

控制品质的其中一个环节就是控制公差,这是为什么说将质量嵌入到产品设计当中的原因。公差将直接影响产品的一致性,稳定性,可靠性和功能。公差设计出来比较容易,但是如何将公差控制在一个有限的范围内却是一件困难的事。这是为什么美国在二次世界大战20世纪40年代期间,为了确保军工产品的品质,而培养以万计的工程师来研究统计过程控制的原因。统计过程控制的目的就是为了将超出公差的产品缺陷数量最小化,而且在过程即将产生不良品之前能够提前通过图形趋势的形式告知工程师调查原因采取预防措施。

One of the steps in controlling quality is to control tolerance. This is why quality should be built in product design. Tolerance will directly influence the consistency, stability, reliability and functions of products. It is easy to design tolerance, yet it is difficult to control the tolerance in a limited range. This is why America cultivated over ten thousands of engineers studying the control in statistical processes to ensure the quality of military products during the 1940s. The aim to control statistical process is to minimize the product defects which exceed the tolerance, and to inform the engineers of the investigation reasons to take precautions via the form of graphic trend in advance before producing defective goods.

公差并不是指时而能做到,时而又不能做到,这并不是好的品质,而是指长期稳定的能满足,这就是所说的可靠性。有一个笑话说日本产的吊车和某国产的吊车,日本产的吊车声称能吊起一百吨重的货物,你如果让它吊105吨重,吊臂就断了,而某国产的吊车声称能吊起150吨重的货物,但是10里面有一次只能吊起80吨重的货物,也就是说在80吨重的货物即将被吊起的时候吊臂断了,不敢想象结果如何,而这就是稳定性和可靠性不同的结果。

Tolerance does not mean that sometimes we can achieve it while sometimes we cannot— Instead, it refers to the ability to achieve a long-term stability, this is the so-called reliability. There is a joke: cranes manufactured in Japan claim that it can lift cargos up to 100 tons. If you lift cargos of 105 tons, the arm will break. Cranes from another country claim that it can lift cargos up to 150 tons, but it can only lift cargos of 80 tons once in ten times. That is to say, the arm breaks when the 80-ton-cargo is about to lift. The outcome seems to be beyond the imagination, and this is the consequence resulted from stability and reliability.

公差的给定来源于对实际工序制造能力的了解,同样的产品设计可能德国和日本的公差就给定的相对来讲比较小,是因为他们的工序制造能力比较强,加工精度比较高。就像在一个展会上面所展示的国产的轴承可能转一分钟就停止了,而德国产的轴承可能十分钟还没有停下来。同样,我听说日系车的配件的零售价比德系车的配件的零售价要高,因为德系车的零部件,从仓库挑一个配件出来,不一定能和原车的其他部件尺寸相匹配,而日系车从仓库随便挑一个零部件出来,都能和原车的其他部件完好匹配。你可以想象德系车的配件的不良浪费是不是会比日系车的配件的不良浪费要更多呢?

The given tolerance resulted from understanding the manufacturing capability of actual process. With the same product design, the given tolerance from Germany and Japan will be relatively small because their capability of manufacturing process is strong and their processing precision is high. For instance, the domestic bearing exhibited in an exhibition can only rotate for one minute, whereas bearing produced in Germany can keep rotating for at least 10 minutes. Likewise, I heard that the retail price of accessories from Japanese cars will be higher than those of German cars, as the randomly selected accessories of German cars from stock is unable to match other accessories of the original car, while those from Japanese stocks can be perfectly matched. You can imagine that the unnecessary waste of accessories of German cars will be much more than that of Japanese cars.

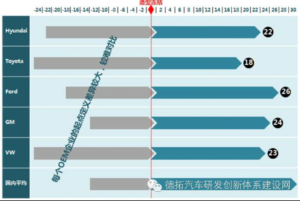

我们谈供应商早期参与,其中一个目的就是希望对供应商的制造能力提前有所了解,也希望供应商对产品公差设计的期望有所了解,这样要求和实际能力才能更好的匹配,在产品的设计环节和图纸规格的评审环节能够尽量缩短时间,而不是反复的打样,修改。丰田从产品概念的设计冻结到批量生产的周期是18周,这比现代的开发周期短了近一个月,而比美系车和国产车的开发周期短得更多,尽管这个开发周期考量公司开发产品的综合能力,但众所周知,丰田同供应商的关系紧密程度要远远强于美系车和德系车同供应商的关系,可见供应商早期参与对提升产品设计,以及缩短开发周期都是大有裨益的。

One of the aims that we talk about the early engagement of suppliers is that we hope to understand the manufacturing capabilities of suppliers in advance, as well as expect suppliers to understand the expectations of designing product tolerance. Therefore, the requirement and the practical ability can be matched better, reducing the time of designing the product and reviewing the drawing specifications instead of repeating proofing and revising. The cycle of Toyota from freezing the product concept design to batch production is about 18 weeks, which is nearly 2 months shorter than Hyundai. What’s more, the period is even much shorter than that of American cars and Chinese cars. Although this development period examines the comprehensive ability of a company in developing products, it is well-known that the relationship between Toyota and its suppliers is much closer than that of the American or German automobiles with its suppliers. Therefore, it can be concluded that early engagement of suppliers is beneficial for both improving the product design and shortening the development period.

回到开头的故事,如果我们反过来先将对衣服的尺寸的要求作为一个公差进行管理。比方说公差限制在32到34码之间,那这时对品质就有要求了,目标有了,接下来就是方法。方法可以是多样的,就像工厂之内公差的管控也可以有多种方法。而锻炼就如同去改善,持续的健身,就如同持续改善。

回到开头的故事,如果我们反过来先将对衣服的尺寸的要求作为一个公差进行管理。比方说公差限制在32到34码之间,那这时对品质就有要求了,目标有了,接下来就是方法。方法可以是多样的,就像工厂之内公差的管控也可以有多种方法。而锻炼就如同去改善,持续的健身,就如同持续改善。

Let’s come back to the story at the beginning. If we regard the requirement on clothing size as a tolerance to conduct management—for instance, limiting the tolerance from 32 to 34— then the quality is under requirement. Since we have the objectives, and the next is the method. Methods can be various, just as the methods of controlling tolerance within a factory can be various. Exercising is like improving, and continuous exercising is like continuous improving.

让你永远Slim,让你的工厂保持一种长久的Lean的状态吧。

Let you be slim forever, and let your factory keep lean always.

Great Acknowlegement Given to Ms. ZiZhu Wang (Akiko) from GuangDong University of Foreign Studies for Translation.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

try more

Pingback: 供应商开发里程的实践 Supplier Development JourneySupplier Lifecycle Management供应商全周期管理 | Supplier Lifecycle Management供应商全周期管理