Views: 549

继文章“一个商务访问者眼中的德里”之后,推出新篇“印度工厂印象”。近些年印度也在大力发展基础设施,而随着基础设施的建设,也带动了印度的工业发展,准确的说是制造业发展,甚至中国也有企业开始进驻印度设厂以开发本地市场,比如笔者就有认识的朋友服务于国内某知名手机制造商,被派往印度支援并指导生产本土化。加之传统的制造大国中国的人工成本一路上升,出口印度的关税仍然高居不下,而与此同时印度同许多周边国家加强了关税互惠政策,以增强自身的出口竞争力,印度的制造业面临很大的发展机遇。尽管近期印度2017年度第一季度的GDP为不尽人意的5.7%,广泛的国际国内评论把这归咎于总理莫迪的去年底的“废除大额面钞”和今年的“税率统一”新政,但哪一个发展和转型没有经历过阵痛期。长远来看,越是欠发达的地区越是发展机遇广阔,何况印度有和中国一样多的人口基础。

Here is a new article The Impression of Indian Factories after the previous Delhi in the Eyes of a Business Visitor. In recent years, India has been vigorously constructing infrastructures, which has also promoted the development of its industry, or manufacturing exactly. Even Chinese businesses start to set foot in India to explore the local market. A friend of mine, say, who works for a well-known cellphone manufacturer in China, has been sent to India to assist and guide production localization. In view of the fact that China, the traditional manufacturing country, sees a continuous increase in labor cost and puts high levies on export to India and that India has enhanced the tariff policy of mutual benefit with many peripheral countries to improve its export competitiveness, the Indian industry promises rosy opportunities for development. India reported a disappointing GDP growth rate of 5.7% for the first quarter of 2017, which broad national and international comments attributed to Premier Modi’s abolishing large-denomination bills last year and the new policy of flat tax rate this year, but it is normal that each entity that is developing and transforming goes through difficulty. In the long run, the less an area develops, the more opportunities it possesses for development; moreover, India has as large population as China.

因为工作的关系,笔者有机会在过去4年间拜访了印度7家建筑五金类产品的外销型制造型企业,分布在印度的不同城市。因为没有更加深入的了解,只作经历当中事实性的陈述和部分个人观点供参考。

因为工作的关系,笔者有机会在过去4年间拜访了印度7家建筑五金类产品的外销型制造型企业,分布在印度的不同城市。因为没有更加深入的了解,只作经历当中事实性的陈述和部分个人观点供参考。

In the past 4 years, I paid business visits to 7 export-oriented manufacturing enterprises of building hardware located in several cities in India. Due to a lack of further investigation, I will only make factual statement of my experience and provide personal thoughts for reference.

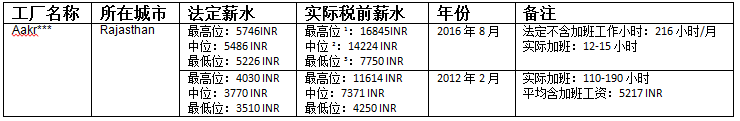

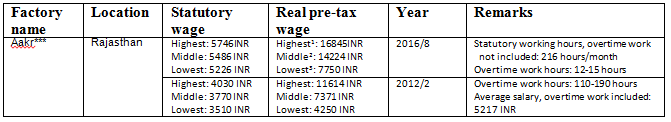

这些工厂的一些基本信息如下:

Here is the basic information of these factories:

所拜访的这些印度工厂的工作时间基本以09:00 – 17:30 为主,中间30分钟吃饭,外加上午15分钟的茶歇和下午15分钟的茶歇,所谓的茶歇就是打铃休息,有人说东南亚的一些工厂员工难以管理,“他们中间要拜神”,其实说的就是茶歇时间,既然是休息时间,当然员工可以自由利用。

These factories have a working time that mostly falls in between 9:00 and 17:30, with a 30-minute interval for meal and a 15-minute tea break both in the morning and in the afternoon. A tea break is when the workers have a rest. Some hold that southeast Asian workers are hard to manage, saying “they have to worship gods during work.” This is what takes place in the tea break, which, being a time for rest, can be definitely used by the workers freely.

中间的吃饭时间通常是13:30 到14:00,这是我第一次去拜访当地的分公司不习惯的地方,到了中午12:00,没有人过来安排我去就餐,还以为出了什么差错,结果到了13:00,才有负责接待的同事过来打招呼说半个小时后去饭堂就餐。当时分公司的办公室在GURGAON一个商业片区,食堂就在公司楼下,属于私人承包的那种,点餐就像大学里见到的饭堂一样。工厂一般是没有配食堂的,员工到带餐或者到外面自行解决,至少不需要配微波炉,食堂和微波炉都不属于设立工厂的基本要求。

Lunch usually begins at 13:30 and ends at 14:00, to which I was not accustomed the first time I visited a local branch. I supposed lunch at 12:00 but it was not until 30 minutes later that I was informed by a colleague of the lunch in another 30 minutes. The branch office was sited in a commercial district in Gurgaon. Downstairs is a privately contracted canteen where food is served in a university way. Factories are not equipped with canteens, or at least microwaves, so the workers bring their meal to work or eat outside.

通常工厂在正常的工作日内会有2个小时的加班,而这也是法律许可的,在此之外,每周6天的工作制也是法律许可的。也就是说正常的下班时间是19:30,何况加班是常见现象,如果工厂是在大城市比如德里,那么绝大部分的员工都会是外地移民,如果员工不是住在工业区附近,由于德里常年不分时段交通堵塞,那么1-2小时的车程是肯定需要的, 9点钟左右到家才能吃上晚饭,所以11:00 到 12:00 才能上床睡觉非常正常,这与我所理解的健康养生时间表相差太远了。甚至我认识的一个当地企业主每天晚上要看2-3部好莱坞电影到凌晨3-4点钟,常年如此,真是让我不可思议。在大城市的工厂,对于普通员工来讲,大部分还是属于外来移民,就像国内背井离乡到大城市打工一样。在偏远一点的城市,工人以本地人为主,而所有印度工厂都是不配宿舍的,针对这点,当地企业主纷纷对中国企业配有宿舍表示好奇。这些外地移民就只有到附近村里或者搭乘公共汽车到远一点的地方租房居住,我想要是企业能配有宿舍给员工,那将真是一大福利会吸引不少优质员工。以德里为例,维基上说有1700万,而百度上说有2600万,而后者更加接近我当地朋友的数据,而这个数据里面70%是外地移民,可见每个首都都是淘金之地,得利益的是当地居民。

Usually, the factory will have 2 hours of overtime within normal working days, which is also permitted by law, and the 6 workingday/week is also permitted by law. That is to say the normal closing time is 19:30, taking into consideration that overtime is common. If the factory is in a big city like Delhi, then most of the employees are immigrants. If employees do not live near the industrial zone, 1-2 hours’ drive is certainly needed before arrive at home at around 9 o’clock due to perennial traffic jams in Delhi. So go to bed at 11:00 to 12:00 seems very normal. This is, however, far from what I know as a healthy living schedule. Even a local business owner I know watches 2-3 Hollywood movies every night till 3-4 in the morning, year in and year out, which is really incredible to me. The general staff in factories in big cities are mostly immigrants, just like those in remote villages in China crowding into big cities looking for a job. workers in far flung cities are mainly local residents. Indian factories are not equipped with dorms, local entrepreneurs are surprised about Chinese companies with dormitories. Those immigrants have rent a living place in a neighboring village or somewhere farther. if a business can provide accommodation to employees, it will help to attract many high-quality employees. In Delhi, for example, WIKi mentioned a population of 17 million workers while Baidu mentioned 26 million, but the latter is more close to the figure by my local friends. and of the figure, 70% are immigrants. Obviously, each capital is a place for gold rush, the benefit of which go to the local residents.

同越南恰恰相反,印度的女性是较少工作的。在印度,仅有三分之一的女性有正式工作,而在越南国内私营企业中女性老板甚至高达25%。在笔者去过的那些印度工厂可以印证,其中一家工厂90%的男性,只有10%的女性。他们骨子里就是瞧不起女性的,但是嘴里当然不会这么说,毕竟现在这个世界,由于信息的畅通八达,知识和文明的快速传播,大家对于很多不合理的现象已经有进一步的认知,只是限于历史和文化的原因短时难以转变而已。

In contrast to Vietnam, few Indian women choose to work. In India only one third of women have a formal job whereas in Vietnam women account for 25% of private enterprise bosses. In one of the Indian factories I once visited, male workers take up 90% while female, 10%. They despise women, a truth they don’t speak out. After all, thanks to the fast spread of information, knowledge and civilization, people have updated their recognition of many unreasonable phenomena, but are not able to make a quick shift of mind due to historical and cultural factors.

以笔者所在的行业为例,在印度也有不少的同行制造业,但是大都处于单一部件的生产制造,较少有完整的复杂产品的生产到组装一条龙服务,当然也不排除一些本土和外资大企业资金雄厚,在当地设厂生产摩托车,汽车,卡车,空调等商品。而究其原因,笔者把它归之于以下:

Take the industry where I am as an example. There are many manufacturing businesses in India, most of which produce single parts with a few being able to cover both the production and assembly of a complicated product. Of course, there are still several rich enterprises locally owned or run by foreign capitalists, which produce motorcycles, automobiles, trucks, air conditioners and so on. As for the reasons, I conclude them as follows:

基础设施的匮乏。中国有句古话叫要致富,先修路,说明基础设施对于企业和地方发展的重要性,而印度的基础设施给笔者的印象是很多地方相当于中国90年代的水平,以德里为例,货物从德里运送到孟买需要1,100公里的陆上运输,这大概需要20多小时。在笔者2017年9月份拜访一家NOIDA工业区内的企业的几天当中,每天都会发生突然断电的现象达5次之多,幸好企业配有应急发电机组才不影响生产。而这大大制约了他们的发展,这也是他们近些年花大力气下功夫的地方。

Lack of infrastructure. An old Chinese saying—if you want to get rich, build the road first—manifests the importance of infrastructure in the development of enterprises and local economy. Yet in my opinion,the infrastructure in India, however, equals to that of China in 1990s. In Delhi as an example, land transportation of goods from Delhi to Mumbai follows an above-20-hour route of 1,100 kilometers. During the time when I visited a company in the NOIDA industrial zone in September, 2017, power blackout recurred as many as 5 times every day. So the enterprises had to be equipped with emergency generator sets to sustain production. This, however, has greatly hampered their development, and is where they have made great efforts to improve in recent years.

基础设施缺乏带来的弱国际竞争力。中国早些年的低成本快速发展已经将低端产品渗透到印度本地市场,在印度当前整体消费能力水平低下的基础上在印度你会发现非常多的商品都是中国造。中国批量低成本制造,这直接打压了印度本地企业在低端市场发力的信心。而在中高端市场,无论是人才或是技术,设备,供应链都是短板。在笔者所见的这些企业中,他们都沉淀了10-20年,供应链相对完整,但是也免不了很多工序都自己来做,因为外发实在不是明智之举,供应短缺,品质问题可能会让你无法向你的欧美客户按时交货。在印度,知名的世界500强投资设厂的实在不多,而在中国,截止2008年就有480家进驻中国投资设厂、建设研发机构、或是设立常驻机构,这也影响了各国投资者向印度投资和采购商品。

Weak international competitiveness resulted from the lack of infrastructure. The local Indian market has been penetrated by low-end products from China which developed in a low-cost yet fast way. In India where the overall consumption ability remains low, you will find many goods made in China. China’s mass low-cost manufacturing directly suppressed the confidence of the local Indian enterprises in playing in the low-end market. In terms of the high- and middle-end market, India is inadequate in no matter talent, technology, equipment or supply chain. For those enterprises which I saw having a relatively completed supply chain after 10 to 20 years’ development, they choose not to outsource many producton processes but do them on their own for fear that supply shortage or quality problems that may otherwise occur to prevent timely delivery of goods to European customers. In India, few of the world’s top 500 companies have made investment, but in China, 480 of them have already invested there for factories, R & D institutions, or representative offices. This has also imposed a negative effect on investment and purchasing in India from other countries.

(2016年德里的一个普通集市,大部分商品中国货A common fair in Delhi, 2016, most commodities made in China.)

(2016年德里的一个普通集市,大部分商品中国货A common fair in Delhi, 2016, most commodities made in China.)

印度的信仰文化。印度繁多的教派和宗教人士(据说印度有3亿神灵)),以及历史上2000多年的种姓制度大大限制了人们突破传统人生观的欲望和勇气,处在金字塔底端的大量的普通民众从内心就认为这辈子,乃至下辈子都与财富无缘,说的难听就是不求上进,容易满足,从而丧失了打破现有条条框框的胆识和勇气,而社会对此也不支持,因此贫富差距悬殊。但是每个社会拉动经济发展的都不是那些掌握社会绝大多数资源的少数派和国有企业,而是数量庞大的中小企业。

The Indian religious culture. Enormous sects (India is said to have 300 million gods) and a large religious population plus the caste system that has lasted for 2000 years has greatly limited the Indian people’s desire and courage to break through the traditional outlook on life: people at the bottom of the pyramid take it for granted that there is no way for them to be rich, be it in this turn of life or a next one. Therefore, they are easy to be satisfied and make no progress, losing the courage and insight to go off the existing dogmas,the breach of which is, actually not supported by the society.This partially accouts for the huge gap between reich and poor. But it is not the minority and state-owned enterprises which hold the vast majority of the society’s resources that drive the social economic development, but a large number of small and medium-sized enterprises.

精英教育。教育的规划政策有明显问题。政府在高等教育和基础教育投入的钱差不多,在教育政策上也是二元制一刀砍平。这种搞法,现在看来是有比较明显的问题在里面。

Elite education. The educational planning is obviously problematic. The government spends roughly the same amount of money on higher education and basic education, and adopts a binary system in the education policy. This sort of policy now prove troublesome.

比如,高等教育有其特殊性,在严格的印度教育选拔制度上,高等教育其实人数较少,精度要求较高,呈现精英化的特点。而这类高等教育的教育政策和经费把控上,是很明显需要特别对待的,不适合和基础教育一刀切。

For example, the higher education has its own particularity. Under the strict selection system in Indian education, people able to receive a higher education is actually small in number and higher in accuracy, which is characterized by elitism. The education policy and funding of this type of education are obviously required to be treated in a special way; it is not suitable to regard it as equal to the basic education.

但是这还不是真正的问题,真正的问题出现在基础教育上。 基层教育的人数更多的,范围也更广泛,并且也承担着消灭高文盲率以及提高国民教育水平的重任。印度基础教育分为两种,一种是公学,还有一种是私学,也就是常见的西式教育分法。公学承担更广泛的基础教育,虽然免费的初等义务教育已经在2001年被写入法律,但教育质量很差,不及格率很高。

But the true problem underlies the basic education. The basic education is oriented to a larger population, spread in a wider range, and takes the responsibility of reducing the illiteracy rate and improving the national educational level. The Indian basic education is divided into two kinds, one being the public school and the other the private — the common western education classification. The public school undertakes much more responsibilities of basic education. Although the compulsory education has been written into the law in 2001,education quality is poor, leaving a high failure rate.

印度政府还是做了一些努力,比如在2001年的Sarva Shiksha Abhiyan,或称为全体教育激励计划,很大的提高了入学率。 但是”入学率”虽然提高,但是毕业率变得更差。 同时在这种经费也一刀切情况下,老师的雇员数不够用,给老师的待遇不可能很高,也招不到很高素质的老师 私学虽然可以办到这一点,但是高昂的教育费用必然只能提供给高阶层人士,而且数目不多,涵盖不广,也承担不起”改善国民素质“的社会责任。

The Indian government has still made some efforts, such as the Sarva Shiksha Abhiyan in 2001, or the whole education incentive scheme, which has greatly increased enrolment.But the enrollment rate increases at the cost of decreasing graduation rate.Meanwhile, the expenditure being divided equally among the basic and higher education, teachers are not adequate and the treatment of teachers can not be high. As a result, high-qualitied teachers are deficient.Although the private school may make up the above shortage, it requires large amounts of fees so it can be only afforded by people of higher class. Besides, the number of the private schools are relatively small and the orientation is not wide, so it cannot take the social responsibility of “improving the national quality”

以上原因综合到一起的表现就是全印度的文盲率高达三分之一。2011年印度的识字率甚至赶不上1990年时的中国。2013年印度成年人曾在校受教育的平均年限与1985年的中国持平。 关于更多印度制造业不济的政治,文化,体制上的评论可以参考网络上的一些评论,比如“为什么印度在经济方面发展得不如中国好?”(来源:https://www.zhihu.com/question/20992832)

The above reasons add up to the fact that the illiterate rate is up to 33%. The literate rate of India in 2011 was not even as high as that of China in 1990.In 2013, the average years of an Indian adult for school education was equal to that of China in 1985.For more political, cultural and systematic comments on the poor Indian manufacturing, refer to those on the Internet, for example, “Why India falls behind China in economy development?” (Source: https://www.zhihu.com/question/20992832)

印度的效率实在不敢恭维。这不仅在工厂内部可以看到,而且在日常生活中也可以体会到。在工厂,员工只管按要求例行公事,尽管有获得ISO9001证书,但持续改进还有很大的空间,做错了就错了,再返工,不去思考如何去修正或者预防。笔者在印度的一家生产门合页的企业,良率比国内同行低了两位数。员工包括企业主还没有上升到考虑效率和生产节拍的层面上来,造成交货不稳定。在印度,大家一致的看法是讨论很多,实施很少,估计和多党派政府执政有关系。你会看到很多在马路上聊天的人,不知道在聊什么。而在酒店,区区一个大堂,我就发现4个人无所事事的样子,当然这里面包含有个拿着苍蝇拍忙于寻找并拍打苍蝇。(这不包括负责柜台内负责办理入住和离店的人员)。

There is nothing for India to boost about its efficiency, neither in factory production nor in daily life.In factories,the workers are regulated to do a routine job, with no need for thought or consideration for improvement. The quality yield of an Indian company which produces door hinges is lower than that of the domestic peers in double digits. Employees and even business owners don’t take production efficiency and tempo into consideration, resulting in erratic delivery. A common impression of India is that words are more said than done, which is supposed to have something to do with the multi-party government. You can see many people chatting on the street, having no idea what they are actually talking about. Just in one hotel lobby, I found 4 people hanging around doing nothing, including one busy looking for and slapping at flies. (This does not include those responsible for hotel check-in and check-out.)

印度的产品也有出口欧美,但是笔者的印象是限于一些手工业产品和少数中高端制造商品。本地市场仍然 有广泛的需求,但是以中低端为主,就连本地最大的汽车制造企业TATA也是主推价格在10万人民币以内的私人轿车。笔者所在的行业向印度采购的商品基本上没有测试条件来验证产品的可靠性,而生产的数量上比国内企业低好几个级别,也限制了规模化效应和质量控制上的投入。对于供应链的管控基本上只在汽车制造业里才有实施,因此供应的原材料没有保障。以笔者熟悉的一家五金单品加工企业为例,采购不锈钢棒,尺寸可以测量,材料成分每批都送外检验,但是硬度就不稳定,加工出来的产品总是有毛刺或者尺寸不稳定。而检验硬度的设备没有配备,即便是配备,其实也改变不了现状,钢材厂基本上都是大企业,作为小客户只有使用的份,没有改变的权。作为最基本的检验工具卡尺,笔者发现的确都有校准,但是就目测质量就明显不如国内的量具大厂生产的。

Indian goods are also exported to Europe and America. But as far as I can remember, these goods contain only handicraft products and a few high-end manufacturing ones. The local market is in a large demand for mid- and low-end products. For example, even TATA,the largest car maker of the country, mainly sells cars that cost within 100,000 RMB. In my industry in India, there is no testing conditions to verify the reliability of the products purchased there; production quantity is far more smaller than that of China, which also hampers the scale of economy and quality control. Due to the lack of supply chain management which is implemented only in car industry, the material supply is unsecured. Take a hardware item processing enterprise with which I am familiar as an example. In processing stainless steel rods, the factory measures the size and sends each batch of materials to external inspection, but the hardness won’t be stable, and the products are always deburred or unstable in size. And there is no device of hardness test. Even if it is in position, it will change nothing because steel factories are usually large enterprises, a small customers can only buy from it, with no rights to it. As for the most basic testing tool caliper, I found that there is indeed calibration, but a simple visual inspection can show obviously that the quality of it not as good as that produced in China.

笔者观察发现印度的企业有20%的设备采购是欧美的,20%钟意台湾的,30% – 40% 是中国产,还有20% – 30% 是本地设备,而往往那些设备都陈旧缺少保养。印度的企业主大都受过良好的教育,还是具有一定视野的,自动化设备也在一些企业开始实施,但是毕竟范围并不是那么广泛。欧美设备精度高,但是价格昂贵,而台湾的设备其实在全球市场都颇受欢迎,因为性价比适中,中国产设备近些年抓住出口的春风发展的也不错,而印度本地的设备仅供一些普通的加工。当地企业主十分满意中国产数控机床CNC,笔者细看发现是大连机床厂生产,并不是说大连机床厂的质量不好,而是国内更加喜欢欧美产的设备。

I found that in India, 20% companies procure equipment from Europe and the United States, 20% from Taiwan, 30%-40% from mainland China and 20%-30% from the local market.their equipment are often lack of maintenance and old. Most Indian business owners are well-educated and have a broad horizon, and have begun to carry out equipment automation—on a primarily small scale. European and American equipment boosts of high preciseness, but are expensive. Taiwan’s devices are actually popular around the world because of its high performance-price ratio. Chinese equipment also develops well in recent years thanks to the encouraging export policies. Yet Indian equipment is only available for some common processings. The local business owners are quite fond of the CNC machine tools made in China, most of which I find are from Dalian Machine Tool Group. In China, however, European and American devices are preferred by the domestic enterprises.

印度法定的工资情况和笔者通过查阅薪水薄所了解的实际工资水平如下。对于白领阶层,笔者在2013年拜访一家企业主时,他指着路边 ADOBE的办公楼自豪的告诉我他儿子在那里工作,月薪水在1万人民币,并表示在同龄白领当中属于佼佼者了,由此可见印度的平均工资水平:

The legal wage level in India and the actual wage level as I know through the payroll sheet are as follows. For the white-collar workers, I visited a business owner in 2013, who pointed to the roadside ADOBE office building and proudly told me his son worked there with a monthly salary in 10 thousand yuan, and that such a salary ranked top among white-collar workers of the same age. The average wage level in India:

1: 取工厂五金开料工人为例 Hardware cutting workers as an example

2:普通操作工Common operator

3:杂工,以女性为主Handyman, women mainly

根据印度1948年工厂法案,如果每天工人工作超过9小时,或者任何一周超过48小时,企业主就需要针对加班部分向员工支付相当于正常工作时间薪酬水平2倍的工资。 这不分正常工作日内的加班或者周末,亦或者节假日通用。但是实际情况中现象往往同国内一样,较少有企业能满足,可见资本家在哪都是一样的。

According to the Indian Factory Act in 1948, if the workers work more than 9 hours a day, or more than 48 hours a week, business owners need to pay for the extra working hours twice the normal salary to the workers, with no exception of working days, weekends and holidays. But the real situation is that few companies can meet this regulation, the same with China. It is apparent that capitalists are the same everywhere.

2017年笔者再同其他的当地企业主私底下聊谈得知15,000 INR 每月应该是德里NOIDA工业区的平均水平,这个金额以当前的汇率计算为1,533 人民币,这也是包含加班费在内的员工月工资。如果不考虑工作效率,相比目前珠三角2,500 – 3,500 人民币每月的普工工资水平还是蛮有竞争力的。

In 2017, I learned in a casual chat with local business owners that the average salary in NOIDA industrial area, Delhi is about 15,000 INR per month, which equals to 1,533 RMB at the current exchange rate. Pay for extra working is also included in. Leaving work efficiency apart, such a salary is competitive in comparison with the current level of 2,500 to 3,500 RMB per month in pearl river delta.

印度作为一个人均GDP为1,678美元(2016年数据)的发展中国家,尽管同中国政府一样制定了诸多的法律法规,但在实际的落实当中企业在合规发展方面仍然有很大的落差。同中国同行的企业一样在工厂内部有诸多问题,但是一些现状笔者真的只在国内的内地一些偏远城市内的企业里见过。

Although India, a developing country with a GDP per capita of $1678 (2016), established a number of laws and regulations as China do, there is a long way to go for these enterprises to play within regulations. Just like its Chinese peers, Indian factories have many problems, but some of which I have only seen in some companies in remote cities in China.

(2016年Rajasthan某企业的铜铸造工序Copper casting in a enterprise in Rajasthan, 2016)

(2016年Rajasthan某企业的铜铸造工序Copper casting in a enterprise in Rajasthan, 2016)

印度政府为了支持企业的发展总是睁一只眼,闭一只眼,或者有选择性的睁眼闭眼,而大部分企业在合规方面的发展并不是来自于自身的主动考虑, 而是来自于客户和市场的需求以及竞争的压力。

In order to encourage the development of local enterprises, the government turns a blind eye to their behaviors against regulations. Most enterprises choose to conform to the regulations not because of initiative consideration of the development of itself, but is force by the customer and market demand and competition pressure.

印度和中国一样有新年,也一样有工人短缺季,但是他们的新年排灯节(DIWALI)在我们公历10月份,而那个时候也并不是工人的短缺时期,因为假期就像我们的五一,或者十一,只休息3天左右。反而大部分企业的工人短缺是在每年的四到五月份,因为那个时候许多的员工需要回老家去收割庄稼,同时那个时期也是印度年轻人比较中意的结婚办喜事的日子。笔者所在的企业前期就曾因此而在交期上饱受折磨,建议如果读者有合作伙伴在印度,需要提前做好备货的准备。

Just like China, India has a New Year and a shortage season of workers.Since their day of New Year—DIWALI, is in October, with only 3 days off, the worker shortage season doesn’t fall in between. The shortage season takes place in April or May every year when many workers ask for days-off to go back home harvesting crops. Meanwhile, it is also a period of time preferred by Indian young people for wedding. My company was once tortured during the period of delivery. So it is a suggestion that if you have any trade partners in India, the goods for delivery should be prepared beforehand.

Special acknowledge goes to Ms. Wang Qian (Claire) from Guangdong University of Foreign Studies for translation.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023