Views: 878

投诉在我们的日常生活中司空见惯,而处理客户投诉成为销售人员的工作内容之一。在一般的公司是销售人员处理投诉,因为客户理所当然的认为货是找销售买的,钱也是支付给销售的,或者至少是支付到销售提供的账号内,因而出了问题,或者有什么不满意当然也是销售负责了。就像采购拿公司的钱去给公司购置了商品,如果质量或者交期达不到要求,当然也应该是采购出面去跟催和协调。在一些有特殊要求比如汽车,食品,药品,化妆品等需要监管的行业则通常设置有特定的售后和客服热线。ISO9000系列中有“GBT 19012-2008 质量管理 顾客满意 组织处理投诉指南”来引导和规范投诉处理的方法及常规流程,但其内容更适用于零售行业。

Complaints are common in our daily life, and dealing with customer complaints has become part of salesmen’s work. In ordinary firms, salesmen are the ones to deal with complaints. Since goods are sold by and money is paid to the salesman, or paid at least to the account provided by the salesman, customers take it for granted that they should turn to the salesman for help once any problem or dissatisfaction arises. For example, a purchaser goes to purchase goods for the company with the company’s catipal, and he will also be the one to negotiate or follow up the process if the quality or delivery falls short of requirement. Some industries with special regulations such as the automobile, food, pharmaceutical and cosmetics are often equipped with after-sales services and customer service hotlines. In ISO9000 series standards, there is “ISO 19012-2008 Quality Management—Customer Satisfaction—Guidelines for Complaints Handling in Organizations” to guide and standardize the ways and conventional processes of handling complaints, which is, however, more applicable to the retail industry.

销售作为一个窗口与客户对接,但不可能全程亲自参与调查与解决。与销售相对应的,则是供应商管理人员或采购在公司内部接到销售或客服传回的投诉后第一时间传递给供应商,当然如果公司本身有制造环节,也会将制造环节或者收料环节发现的供应商不良反馈给供应商,但是笔者更多关注的是从客户端发现的不良反馈回来的。

Salesmen, connecting directly with customers, cannot get fully engaged in problem investigation and adressing personnally. In response to the complaints reported by salesmen or customer service center, the supplier management or the purchaser should pass that message to the supplier immediately. If the company produces itself, it will also return the flaw materials which are identified in manufacturing and receiving inspection processes to suppliers. But here the author cares more about the negative feedback from customers.

投诉涉及到的内容可能千差万别,从交期到服务,价格到质量,作为供应商质量管理,我们首先谈与质量相关的投诉。当然这个质量免不了与价格,服务,交期,数量扯上关系,而且在整个产品周期内可能每个环节都会涉及到投诉,笔者更愿意把项目阶段的质量问题归结到沟通,服务和技术能力,而不当投诉来处理。当然对于项目所谓阶段的定义各种公司都会有稍稍不同的描述,有的会以试产通过评审为界,有的会以第一次批量生产和验货为界,也有的会以样品确认为界。这些都不是争论的焦点。

Complaints can be made on everything, varying from delivery to service, or from price to quality. Since our focus is on supplier quality management, we will firstly talk about quality-related complaints. Of course, this sort of complaints will be inevitably entangled with such terms as price, service, delivery and quantity,and complaints can be involved in every linkage in the whole product lifecycle. The author, however, would rather attribute the quality problems occurring in project phase to communication, service and technical capability than regard them as complaints. Concerning the end of the so-called project phase, different companies have different descriptions. Some refer to a passed trial production, some to the first batch production and inspection, and others to the confirmation of samples. This will not form the focus of our discussion.

哪个部门是发投诉给供应商的最合适部门?看公司结构的设置,各有优缺点。从联络来看,与供应商打交道最多的部门最方便,因为经常打交道,相互熟悉,所以采购人员相对合适,但是他们常常并不是技术的专家,因此对投诉问题的描述和解释并不会十分清晰,况且他们的核心职责是保障交货,对于供应商后续的改善措施也并不会是他们的关注重点;从利害关系来看,谁给生意,定价格,谁最合适,从这个角度看,采购人员不一定最合适,在大多数传统采购架构(相对战略采购)的公司,价格是其他人事先定好的,生意也是其他部门定好的,采购人员只是负责订单的执行,因此他们其实对供应商没有特别大的影响力,因此反而是产品部或者技术部等更加合适,但是有一点如果是交货的数量成整箱的不一致,采购人员倒是在公司发正式的投诉给供应商之前有必要好好的检查一下是否存在之前沟通上的偏差-这并不奇怪,因为极有可能本来要一批货一起走的,结果因为各种原因最后被分批发走了,这不能算作给供应商的投诉。但是产品部或者技术部往往更加关心产品设计如何更加优化来避免今后的失误,反而遗漏了短期的措施以确保及时供应;从系统性的跟踪验证供应商的改善措施以及协调内外部的围堵措施来看,非供应商质量管理人员莫属了,因为他们的专长是系统思维,但是他们又有一种替别人背黑锅的感觉 – 不是我犯的错,结果总是被一圈人追着要货物,要赔偿,要讨债。如果三个甚至更多部门都同供应商对口来反馈投诉,又反而给供应商一个错误的信号 – 到底我应该听谁的?因此如何设计这个对口环节,看公司的具体情况来定。然而无论哪个岗位被定义为主要的窗口,其实都不影响整个投诉的处理是以团队的形式存在的,只是有主有辅而已。

Which is the most suitable department to deliver the complains to the supplier? Judging from the company structure, each has its own advantages and disadvantages. In terms of communication efficiency, the department that deals with the supplier most suits the job best. In this sence, the purchasers are the right person because they and the suppliers are familiar with each other due to frequent interact. But the concern are that purchasers are often not specialists in technique, having no clear idea about the complaint issues and that their core responsibility lies in the guarantee of goods delivery, so the suppliers’ follow-up improvement measures will not take up their focus. In term of interests, that who signs the contract and makes the price is the most appropriate. In this respect, the purchaser is not necessarily the most appropriate. In most companies with a traditional purchasing framework (relates to strategic purchasing), the price and business are well set by other departments before purchasers just fulfill the orders. So they actually have no enough influence on suppliers; instead, the product development or technical department is more suitable for the job. But notice one thing that if there exists discrepancy by case in the quantity of delivery, it is the purchaser that should make a careful check on the possibility of previous communication deviation before a formal complaint is sent to the supplier by the company. This is not surprising: It is likely that goods to be shipped in the same lot are finally delivered by partial shipment due to various reasons, which can not count as a justification for a complaint for the supplier. In contrast, the product development or technical department who often cares more about how to optimize product design in order to avoid future mistakes may overlook short-term measure to ensure timely supply. Judging from the ability to systematically track and check the improvement measures by suppliers and carry out containment action to coordinate the internal and the external, the job cannot be taken up by anyone other than the supplier management, who thinks in a systematic way. But they might feel themselves holding the bag for others—it is not my fault; why is that I shoud be the one to be claimed to on goods, compensation and debts. If three or more departments feedback at the same time to the supplier, they give the supplier a wrong signal – who should I listen to? So design of the feedback linkage shoulddepend on the specific situation. However, no matter which one is nominated as the main contact department, it does not deny the fact that the whole complaint handling is processed by a team. The only difference lies in who should take the major responsibility and who does the minor.

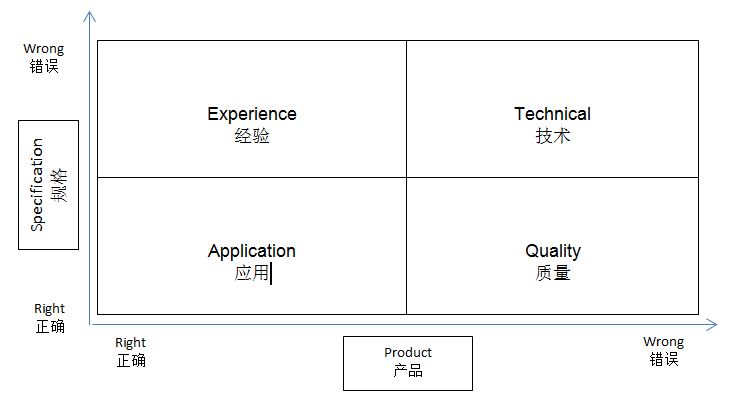

投诉的分类离不开以下的类型,要么规格错了(这里指产品的各类技术文件或者封样),要么产品错了(这里指产品性能不达标),当然也有的时候是两者都错了,也有的时候是两者都没有错,这时经常投诉是以抱怨的形式发生。 第一类情形是如果两者都错了,通常技术是主要原因,因为很有可能是因为技术原因造成规格错误,比如客户买了一批螺丝,买回来发现一拧螺丝头就因为太软而滑牙,但同时发现螺丝的规格资料里就没有关于硬度的说明,尽管不滑牙是螺丝默认的质量特征,但是仍然需要明确规范相应的质量要求。第二类情形是也有可能规格是正确的,但是产品仍然不达标,比如在以上的例子中有明确的螺丝的质量要求,但是螺丝仍然滑牙,那这时品质人员就需要好好的运用各种品质工具调查一下原因了。第三类情形是产品性能良好,但是规格不正确,其原因往往是员工依赖经验生产,没有遵循规范的管理,“幸运”的做对了。第四类情形是规格与产品都没有错误,但是就是客户不满意,而原因很有可能是应用错误,客户是上帝,没有必要与客户发难,反而这个时候更考验服务人员的沟通水平。就像抽屉是用来储物的,但是有用户将它打开来作为登高取物的阶梯,如果没有超出它的额定负重但是抽屉塌了也可以算得上质量问题,但是如果是个大胖子踩在上面不仅塌了而且还摔跤了,也算不上制造商的问题。

第一类情形是如果两者都错了,通常技术是主要原因,因为很有可能是因为技术原因造成规格错误,比如客户买了一批螺丝,买回来发现一拧螺丝头就因为太软而滑牙,但同时发现螺丝的规格资料里就没有关于硬度的说明,尽管不滑牙是螺丝默认的质量特征,但是仍然需要明确规范相应的质量要求。第二类情形是也有可能规格是正确的,但是产品仍然不达标,比如在以上的例子中有明确的螺丝的质量要求,但是螺丝仍然滑牙,那这时品质人员就需要好好的运用各种品质工具调查一下原因了。第三类情形是产品性能良好,但是规格不正确,其原因往往是员工依赖经验生产,没有遵循规范的管理,“幸运”的做对了。第四类情形是规格与产品都没有错误,但是就是客户不满意,而原因很有可能是应用错误,客户是上帝,没有必要与客户发难,反而这个时候更考验服务人员的沟通水平。就像抽屉是用来储物的,但是有用户将它打开来作为登高取物的阶梯,如果没有超出它的额定负重但是抽屉塌了也可以算得上质量问题,但是如果是个大胖子踩在上面不仅塌了而且还摔跤了,也算不上制造商的问题。

Complaints arise in one of the following situations. It is something wrong either with the specification (here it refers to all kinds of product technical documents or sealed samples), or with the product (here it refers that product performance is not up to the standard), or with both the specification and the product. Sometimes there is nothing wrong with the two factors and complaints tend to be ungrounded. If both the two factors are wrong, technique is often the major cause. It is likely that technical errors give rise to wrong specifications. For example, a customer buys a batch of screws, only to find that the screw head is so soft that the driver slips easily. Meanwhile, the customer notices that in the specification list there is no information on the screws’ hardness. Although being unslipped is a default quality of a screw, a clear instruction on the product’s application conditions is still necessary. In the second scenario, the specification may be right while the product is not up to the standard. In the above case, again, if there is a clear product instruction on application conditions but the screw slips still, the quality management is ought to take efforts to find out the causes with all kinds of quality management tools. In the third scenario, the truth is that the product is good in performance while something is wrong with the specification. It is often because the employees do their work with experience, not following standardized regulation. They just do it right “luckily”. In the fourth one, whereas both the specification and the product are right, the customers won’t feel content. Such discontent may originate from wrong application. The customer is always right; there is no need to conflict with them. Instead, this is an occasion to test the communication proficiency of the service personnel. Drawers are designed for storing, but there are some people who use them as stairs to reach something in a high position. If the person’s weight does not surpass the rated weight limit but the drawers fall down, it also counts as a quality problem. But if the person is so fat that the drawers collapse and the person fall down, it does not count as a quality problem.

既然投诉不可避免,解决起来就需要讲究技巧,因为如果投诉处理得当也可以增强客户满意度并确保客户忠诚度,就如同国家维系社会与国际稳定。如果说国民的日常大小纠纷在处理手段上讲究小分歧靠调解,中争端走法律,大事情靠政治,那么大体上笔者把投诉的处理分为三个层面,关系层面,逻辑层面,法律层面。

It needs skills to handle complaints, which, if properly handled, can strengthen customer satisfaction and consolidate customer loyalty. It is the same with a nation to maintain social and international stability. As a nation adapts conciliating, legal and political methods for trouble, dispute and conflict respectively in handlingthe people’s daily issues, the author accordingly divide complaint handling into three levels: the relation level, the logical level and the legal level.

关系层面处理一些不构成客户重大损失或者责任不在供应商的小问题,或者客户的抱怨,主要针对以上分类中的第三和第四类缺陷类型,这时投诉很可能主要是靠电邮,口头告知,甚至对于应用问题,大部分情况下客户是不会告知供应商的,毕竟“家丑不可外扬”。如果私交不错,可能会向供应商诉诉苦。

At the relation level, minor issues that don’t cause severe damages to customers or lay duties on suppliers are dealt with. They are mainly consistent with the third and fourth scenarios mentioned above. Complaints at this stage are mainly made by e-mail or orally. As for application problems, it is something that customers won’t inform the supplier of in most cases. As the saying goes, “It is an ill bird that fouls it’s own nest.” If the customers have good relations with the supplier personally, they may turn to him or her for consolation.

逻辑层面主要考验第一类和第二类投诉的处理。因为无论是质量或者技术原因造成的产品不良投诉都需要周密分析才能最终得出结论是什么原因,需要采取什么纠正和预防措施。一切以事实为重,避免将问题延伸放大甚至人身攻击。一个逻辑能力强的人可能会把对方驳的哑口不言,当然也没有必要让别人“颜面扫地”,因为它毕竟也建立在关系层面基础之上,所有的沟通目的在于解决问题,需要给对方留有台阶。对这个层面的处理,流行的做法是“纠正措施报告分析”,高端大气一点的是8D报告,之所以被称为8D的原因是因为西方人把从问题的分析到解决分为了8个步骤,每个步骤的英文单词以D开头,所以简称8D。

At the logical level, complaints mainly come from the first and second scenarios. Whether product complaints are caused by quality problems or by technical ones, it calls for meticulous analysis for the reasons and rectifying and precaution measures. Respect the fact so as to avoid escalating problems that result in personal attacks. A man of strong logical ability might get the counterpart speechless by arguing. But there is no need to make others lose face completely since this sort of complaints handling is also based on the relation level. The aim of communication is to solve problems, so we should give others an out. At this level, a popular practice is to undertake a “corrective action and analysis report”.More advanced is the 8D report. It is called the 8D report because westners divided the process from problem analysis to problem solving into 8 steps, each one named with a word begins with “D”.

法律层面处理关系层面和逻辑层面都不能解决的投诉。通常大家回复处理投诉的逻辑是“xxx理论上来讲,我们没有出错,或者双方都有原因,但是鉴于双方良好的合作基础及对未来发展的期望,我们愿意xxx”, 这是理与情的结合。只有在最后事情发展到最糟糕的时候才会有人讲“述诸法律”。西方人重理,中方人重情。这个理指的就是道理,情指的就是人情,所以才有一个词叫“情理之中”,说明两者有千丝万缕的关系。当然一旦到达这个层面,往往投诉也拖延了很久了,很多证据就需要前期有较好的保留,而且主导者也不会是单纯的质量或者技术人员,而是从事战略采购及业务关系管理甚至法务的代表。

At the legal level, complaints to be dealt with are those cannot be settled at the above two levels. Generally speaking, the pattern by which people handle complaints is that “…theoretically we have done nothing wrong, or both sides should bear some duties. But in view of the solid cooperative foundation and future expectations, we would like to…” which is a combination of reason and emotion. It is not until things go to its worst that people will resort to the law. Westerners value reason while Chinese people emotion. The “reason” here means principle and emotion means human sentiment. The Chinese word “ acceptable by both reason and emotion” shows the deep relations between the two. However, once things reach this level, it implies that complaints long remained unsettled. In this regard, much evidence needs to be carefully maintained. The leaders will not be just quality or technical personnel, but those engaged in strategic purchasing and business relations management and even legal representatives.

无论是何种类型和等级的投诉,它都需要处理者富有同情心并愿意同对方交谈,将自己设身处地站在对方的角度来看待问题,称呼对方的名字并对事件保持遗憾。唯有客户满意了,才是一个投诉的终结。

Whatever the type and grade of a complaint, it requires the complaint management to be empathy and willing to talk, put him or herself in other people’s shoes to consider problems, and address the counterpart’s name and express regret for what the customer has gone through. A complaint will not end until the customer is satisfied.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023