Views: 3170

所有的生物均是有生命的,而所有有生命的生物均离不开生老病死,就像诗词所说月有阴晴圆缺,参天大树也会有枯萎的一天。人的生命也是有终止的,从哇哇落地到入土为安,谁也无法避免,无非有的人寿命长,有的人寿命短而已。而相对于人,关系有建立也有断割,夫妻关系有情投意合,也有同床异梦,朋友有两肋插刀,也有分道扬镳,上至国家与国家,小至个人与个人。

All the creatures have lives so that all creatures alive cannot escape from sickness and death. This is what illustrated by the poem— the moon dims or shines; it waxes or wanes. Even the towering trees will wither one day, let alone human’s life—from cradle to grave. Nobody can avoid it, despite that some people enjoy longer lifespan whereas others possess shorter one. As for human beings, they have to construct or sever relationships. Conjugal relation may comprise perfect matches, or strange bedmates; friendship may include sacrifice or separation, ranging from country to country, to person to person.

自1966年美国哈佛大学教授 雷蒙德 弗农首次提出产品生命周期理论之后,商业领域生命周期理论得到了广泛的发展,先后有人提出并完善了顾客生命周期管理,信息生命周期管理,领导力生命周期理论(situational leadership theory),产业生命周期理论等等。

自1966年美国哈佛大学教授 雷蒙德 弗农首次提出产品生命周期理论之后,商业领域生命周期理论得到了广泛的发展,先后有人提出并完善了顾客生命周期管理,信息生命周期管理,领导力生命周期理论(situational leadership theory),产业生命周期理论等等。

Since Professor Raymond Vernon from Harvard University in America first introduced the product life cycle theory in 1966, the life cycle theories in business domain have developed extensively. To illustrate, the customer life cycle management theory, the information life cycle management theory, situational leadership theory and industry life cycle theory, etc. have been proposed and improved successively.

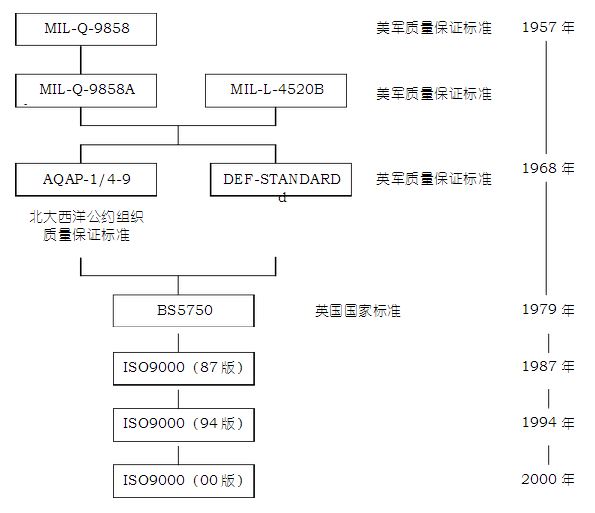

供应商作为业务的不可分割的重要部分进行管理大概可以追溯到20世纪80年代左右,ISO9000-1987版的质量管理系统初次发布的时候,尽管采购活动是更早期就有的事情,但在此之前采购质量的管控更多依赖于对接收产品的检验。

The supplier as an integral part of business for managing can be dated back to approximately the 1980s when the ISO9000-1987 version of QMS (quality management system) was first published. Although procurement had already taken place earlier, the management and control of the quality of procurement was more likely to rely on the inspection of received products.

自从ISO9000 的标准开始建立并强调供应商作为合作伙伴来进行关系管理以来,供应商管理开始进入人们的视野并得到了发展,这包括商务以及技术相关的管理。

Since the standards of ISO9000 were established to highlight that suppliers should play the role of cooperative partners to manage relationship, the management of suppliers, including the business-related management as well as technology-related management, have come to the attention of people, and then developed.

其实供应商与客户之间的关系如同其他周而复始的关系一样, 新的业务关系对于供方而言是新客户,对于需方而言是新供应商,双方建立关系之后既是博弈又是合作,形成一种双风车模式,各自随着各自的风向转动,煞为壮观,直至关系的终结。

In fact, the relationship between suppliers and customers is the same as any other circular relationships. New business relations indicate new customers for suppliers on one hand and new suppliers for demanders on the other, resulting in not only game, but also cooperation for both sides involved. Therefore, a double-windmills pattern is formed with each part rotating with its own direction of the wind splendidly till the end of this relationship.

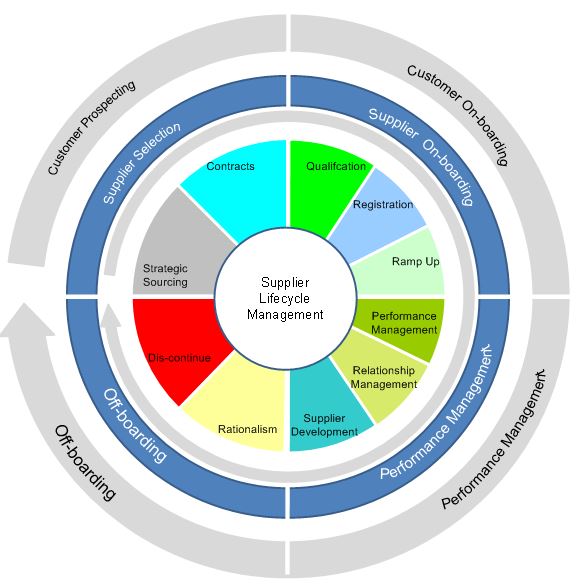

自从有人提出客户生命周期理论,就强调客户具有价值和生命周期。它指从供方与客户建立业务关系到完全终止关系的全过程,是客户关系水平随时间变化的发展轨迹,它动态地描述了客户关系在不同阶段的总体特征。客户生命周期可分为考察期、形成期、稳定期和退化期等四个阶段。关系是相互的,否则是只“沟”但是不 “通”,就像一个人认识国家主席,但国家主席不认识他,这个就不能叫关系,但如果两个人都相互认识,就建立了关系。在相互的关系下,客户实际上也从采购的角度在看待供应商,为方便比较,也大致上可以将供应商和客户的关系分为相对应的四个阶段:供应商的选择,供应商的准入,供应商绩效管理,以及供应商退出。在同一阶段下两者相互关注,相互对视。

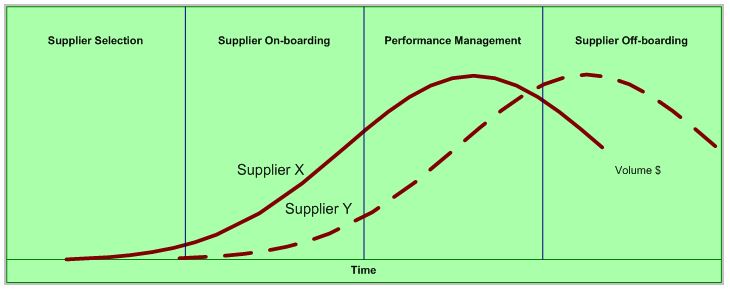

Since someone introduced customer life cycle theory, it has emphasized that customers possess values and life cycle which refers to the whole process from suppliers establishing relations to completely terminating relations with customers. It dynamically describes the overall characteristics of customer relations in different stages. Generally, the customer life cycle can be divided into four phases insisting of prospecting, on-boarding, stabilization and off-boarding. Relationship should be mutual; otherwise, it can only be regarded as transmission rather than communication. Analogously, if someone know the state president, yet the state president doesn’t know him, it cannot be called as relations. However, if two people are familiar with each other, then the relationship can be built. Under mutual relations, customers, in effect, view the suppliers from a procurement perspective. To make it easier for comparison, the supplier-and-customer relations can be also divided roughly into four phases accordingly: Supplier Selection, Supplier On-boarding, Performance Management and Supplier Off-boarding. Under the same stage, the two will pay attention to each other, and stare at each other as well.

“供应商全周期管理基于供应商应该是采购活动及流程的中心的假设,同时能够创造显著的收益。。。。。。将供应商视为生命周期去进行管理可以帮助采购部门在更早的环节将供应商融入到流程中,因而确保其需求可以被更深入,有效的被满足。供应商全周期管理考虑同供应商关系的所有因素,从初期的参与,到信息收集,战略寻源以及合作关系建立再到改善,最后分离”

“ Supplier Lifecycle Management works from the premise that the supplier should be considered as central to procurement activities and processes, an approach which drives significant benefits… Seeing the Supplier as a Lifecycle can help Purchasing departments involve the suppliers earlier in the process so that their needs are satisfied in a deeper more effective manner. SLM considers all the elements of our relationship with a supplier, from initial engagement and information gathering, the sourcing process, through the work relationship, to development and on towards final parting of the ways” (Smith, 2012, p.19).

鉴于客户生命周期理论已经广为人知,而供应商全周期管理相对来讲还比较新颖,因此作者按客户生命周期的顺序来对比介绍供应商的生命周期管理。

Considering that the customer life cycle theory has been well-known while supplier life cycle management is relatively novel. Therefore, the writer will follow the sequence of customer life cycle to compare with and then introduce the supplier life cycle management.

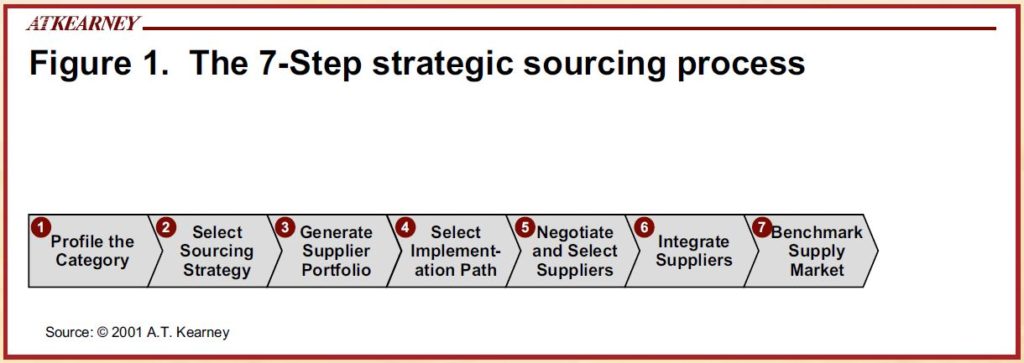

客户考察期(相对应于供应商选择),这个阶段是双方关系的探索和试验阶段,相当于青年男女双方在各自物色理想中的对方。在这一阶段,双方考察和测试目标的相容性、对方的诚意、对方的绩效,考虑如果建立长期关系双方潜在的职责、权利和义务。双方相互了解不足、不确定性大是考察期的基本特征,评估对方的潜在价值和降低不确定性是这一阶段的中心目标。在这一阶段客户可能会下一些尝试性的订单,供方与客户开始交流并建立联系。因客户对供方的业务进行了解,供方要对其进行相应的解答,某一特定区域内的所有客户均是潜在客户,供方投入对所有客户进行调研,以便确定出可开发的目标客户。此时供方有客户关系投入成本,但客户尚未对供方做出大的贡献。相比于供应商考察客户,平衡营销投入与未来收益而言,而实际上,从客户的角度,在这一阶段也面临成本投入与风险考虑,因为客户最终不可能选择很多的合作伙伴来采购有限的物品,因而客户需要花精力和时间以及成本来寻找,拜访,对比最合适的合作伙伴,而且如果选择失误,极有可能给未来的发展造成非常大的隐患,因为毕竟随意淘汰供应商是下下策,很多时候供应商转换成本太大,所以这一阶段的工作称为“战略寻源”(Strategic Sourcing),实践中人们把它会进行细分,下图描述的就是典型的战略寻源。

Customer Prospecting (Supplier Selection): This is the exploratory and experimental stage of the relationship, similar to the process that youth men and women seeking ideal partners. At this stage, the two parties will inspect and measure the compatibility, sincerity, performance of the other, while considering the potential liabilities, rights and obligations of both sides if they are to build long-term relations. The basic characteristics of this period is insufficient understanding and high uncertainty. Thus, the main goal of this period lies in evaluating potential value and decreasing uncertainty. During this period, customers will be likely to make some tentative orders, resulting in suppliers communicating and establishing relations with customers. As customers get to understand the business of suppliers, suppliers should reply to relevant questions accordingly. All customers in a specific segment are potential clients. The suppliers invest in investigations of all clients for the sake of determining exploitable target customers. At this moment the suppliers bare the input cost of customer relations, whereas the customers have not yet contributed significantly to suppliers. Nevertheless, from the perspective of clients, they practically confront problems of cost input and risk consideration compared with suppliers investigating clients, and balancing marketing inputs and future earnings, since it is impossible for clients to select considerable partners to purchase finite goods finally. Therefore, consumers need to take effort, time and money to seek, visit and contrast the most appropriate partners. Moreover, wrong selection will probably give rise to massive hidden danger. After all, eliminating suppliers at random is the worst way as the switching cost of suppliers appears to be too high. Thus, this phase of work is called “Strategic Sourcing”. In practice, people tend to subdivide them. The picture below illustrates typical strategic sourcing.

在笔者的描述里,将战略寻源与各类合同的签订分开,并作为供应商选择,尽管有些对战略采购流程的定义里已经包含合同的签订环节。

在笔者的描述里,将战略寻源与各类合同的签订分开,并作为供应商选择,尽管有些对战略采购流程的定义里已经包含合同的签订环节。

In writer’s description, strategic sourcing is separated from the signing of diverse contracts, and taken as one part of Supplier Selection Process, despite that some definitions regarding strategic procurement flow have already included the signing of contracts.

形成期(相对应于供应商准入),这时是关系的快速发展阶段,相当于男女双方由建立关系到热恋再到进入婚姻的殿堂。供应商和客户双方关系能进入这一阶段,表明在考察期双方相互满意,并建立了一定的相互信任和交互依赖。在这一阶段,双方从关系中获得的回报日趋增多,交互依赖的范围和深度也日益增加,逐渐认识到对方有能力提供令自己满意的价值(或利益)和履行其在关系中担负的职责,因此愿意承诺一种长期关系。在这一阶段,随着双方了解和信任的不断加深,关系日趋成熟,双方的风险承受意愿增加,由此双方交易不断增加。当供方对目标客户开发成功后,客户已经与供应商发生业务往来,且业务在逐步扩大,此时已进入客户成长期,客户可以称为新客户,对于客户而言,这个时候供应商可以称为新供应商。供应商的营销投入和开发期相比要小得多,主要是发展投入,目的是进一步融洽与客户的关系,通过改善产品质量,稳定成本,完善服务等提高客户的满意度、忠诚度以及信心,进一步扩大交易量。此时客户已经开始为供应商做贡献,供应商从客户交易获得的收入已经开始平衡或者大于投入,进入盈利模式,客户也从采购回产品,进行销售开始获利。在此阶段供应商完成所有商务环节的确认正式登记入册,并通过样品以及生产样品的制造流程能力的初步验收,进入几次小批生产或正式订单的爬坡和稳定性确认,通常这个环节的要点是项目质量和快速进入市场的速度。这里所讲的准入并不只是指行政意义上登记注册(Administrative Registration),而是经过反复的实验和沟通确保生产已经能顺利进行。

Customer On-Boarding (Supplier On-boarding): This is the fast-developing stage of the relationship, similar to the man and women evolving from establishing relationship to falling in love with each other, and to entering into marriage. If the supplier-customer relations can access to this stage, both the two sides are quite satisfied with each other during probation with certain mutual understanding and dependence. At this time, return gained from relations is increasing, while the scope and depth of mutual dependence is increasing as well. As they have realized step by step that the other party is capable of providing satisfactory values (or benefits) and implementing its duties in this relation, they are willing to commit to a long-term relation. During this period, with mutual understanding and trust of the two parties deepening, their relationship is becoming mature and their willingness to take the risk is increasing day by day, which result in increasing transactions. When the suppliers develop target clients successfully and the clients start to do business with suppliers, it enters into the customer growing period if the business is expanding constantly. At this moment, customers can be called as new customers, while suppliers can be called as new suppliers. Input over Marketing activities at suppliers is much less than it was in development period since their main focus transfers to development input in order to strengthen the relationship with customers and raise satisfaction degree, loyalty and confidence by improving product quality, stabilizing cost and perfecting services for the sake of increasing transaction volume. This moment the customers have already contributed to suppliers so that suppliers’ gains from transacting with customers become equal or even exceed the input, leading to profit pattern. Simultaneously, customers start to benefit from selling purchase products. In this stage, suppliers need to accomplish confirmation and formal registration of the whole business process, and enter several small-scale production or ramping up and stability validation through official orders by approving samples and passing the preliminary manufacturing process capability checking. Usually the key point of this process is the quality of product as well as the speed of quick entry into market. Here “On-boarding” not only simply refers to administrative registration, but also indicates repeated experiment and communication which aims to ensure smooth production.

稳定期(供应商绩效管理),关系发展的最高阶段,相当于稳定的婚姻,这段稳定可长可短,长了可称为金婚,短了可称为闪婚。在这一阶段,双方或含蓄或明确地对持续长期关系作了保证。这一阶段有如下特征:

1. 为能长期维持稳定的关系,双方都正在或者已经做出了大量有形和无形投入;

2. 交易稳定或者上升。

Stabilization (Supplier Performance Management). This is the highest stage of developing relations, similar to stable marriage. This period can be either long or short—if long, it can be regarded as golden marriage; if short, it can be regarded as flash marriage. At this stage, both two parties implicitly or explicitly commit to continuing the long-term relationship. This stage has following features:

- Both the two sides have already made a considerable amount of tangible or intangible input for sustaining the stable relations for a long time.

- Transactions remain stable or rise.

因此,在这一时期双方的交互依赖水平达到整个关系发展过程中的最高点,双方关系处于一种相对稳定的博弈状态。尽管不同的供应商在稳定阶段表现出不同的对待客户的关系特征,比如从商业价值与吸引力两根轴来看可分为四个象限:开发(Develop),边缘(Marginal),核心(Core),开拓(Exploit)。整体而言,此时供应商的投入较少,客户为供应商做出较大的贡献,初始阶段客户支付相对生命周期其他阶段来讲比较高的价格,带给供应商较大的利润,而且由于客户忠诚度的增加,供应商将获得良好的间接收益,同时供应商与客户交易量处于较高的盈利时期,这个阶段基本上可以称为忠诚客户。而从客户的角度,这段时期因为生产进入稳定环节,质与量齐升,服务水平也因双方相互对需求和困境的进一步深入了解和理解得到了提升,因此此时的关系重点变为进一步推动供应商持续改善(Supplier Development)效率,减少浪费,维持并增长市场份额,以及压缩现有供应商的利润水平,增强抗市场波动风险的能力。实践中人们把这一阶段的活动作为供应商关系管理(Supplier Relationship Management)来对待,认为真正的关系是在这一阶段,估计是因为这一阶段的采购价值在整个生命周期里是最大的。同时作为关系管理的重点,双方都会对对方的绩效进行评估和管理 (Performance Management),供应商会定期评估客户的满意度,采购方会定期评估供应商的各类表现,并进行沟通和交流。

As a result, in this period, the degree of mutual dependence of two sides reaches the maximum point of relationship development process. The relation is in a relatively stable state of game, despite that different suppliers present different relation characteristics of treating clients. For instance, the characteristics can be segmented by two axes—business value and attraction— into four quadrants: Develop, Marginal, Core and Exploit. Overall, the suppliers put less while customers contribute more. In initial phase, customers pay more than in other phases of life cycle, which brings about considerable profits for suppliers. In addition, suppliers will gain good indirect earnings due to increased customer loyalty. Meanwhile, transactions between suppliers and customers remains to be of high profits, and customers of this stage can be called as loyal customers. From the customer perspective, as the production becomes stable, the quality and quantity become balanced, and the service level increase with the two parties’ deepening understandings of the need and dilemma of each other, the key point of relations this time changes into promoting suppliers to improve the efficiency of Supplier Development continuously, reducing waste, maintaining or even increasing the market share and cutting down the profit level of existing suppliers to enhance the capabilities of resisting the market fluctuation. In practice, people treat activities in the stage as supplier relationship management, believing that the real relationship lies in this stage, since the purchase value at this time is considered as the biggest in the whole life cycle. At the meantime, as the emphasis of relation management, both sides will assess and manage the performance of the others. Suppliers will evaluate the satisfaction degree of customers regularly; suppliers will evaluate various performances of suppliers regularly in return with communication.

不同客户的价值是不一样的,客户信息的收集需要一个时间的积累,因此客户的信息的收集也是一个动态的过程,需要在反复的交易中日益完善。最终供应商往往是关注忠诚度最高,供献价值最大的客户,这些也就是重复购买次数及金额居前的客户,从这个角度来看,供应商对客户是有所选择的。同理,客户也从同类型的供应商中来对比其综合表现,决定业务的分配,这也就是跨入下一个阶段的”理性化” (Rationalism)或者说优化(Optimization)。

Different customers have different values. Besides, the collection of customer information requires accumulation of time. Therefore, this is also a dynamic process which need to be improved day by day through repeated transactions. Finally, the suppliers always pay attention to customers with highest loyalty and biggest contribution. These customers are none other than the customers with the most repeat purchases and purchasing amount. From this aspect, suppliers are selective to customers. Similarly, customers will decide how to allocate business based on the comprehensive performance of suppliers of the same type. This suggests the next stage “Rationalism”, or “Optimization”

退化期(供应商退出),关系发展过程中关系水平逆转的阶段,类似于双方对婚姻的厌倦,大部分关系都不会直接终止,而是呈现退化的趋势,就像大部分的婚姻会延续到最后,只是少部分会选择在中途结束。发达国家离婚率会高于发展中国家,比如欧美几个大国普遍在50%左右,排名世界第一的比利时60%,印度以1%垫底,2016年中国离婚率第一的排名北京39%,以国内而言,一线城市又高于二三线城市。排除文化因素,其中一个原因,作者估计是可选择性增强,同时依赖性降低,因为越发达的地方,个人的经济独立自主能力越强。如同在经济发达的国内沿海城市,供应商资源可选择性多,因此关系的维持相对会短些,但以一些小国或者区域例如日本,台湾,韩国,香港而言,供应商同客户的关系延续的时间就明显要更长,因为在当地因为区域的限制可选择性降低,在实际的供应商管理过程中,往往是先导入一个新的替补供应商,同时慢慢退出另外一个供应商,如同下面的形状(也许供应商Y会在更晚一些的阶段出现)。

Customer Off-boarding (Supplier Off-boarding): This is the stage of reverse in relations, similar to boredom on marriage. Most of the relations will not be terminated but will deteriorate, just like most marriages that will last till the end, only few will come to the end halfway. Divorce rate in developed countries is higher than that in developing countries. For example, divorce rate in several big countries from Europe and America is about 50% generally. Belgium ranks no.1 in divorce rate with 60% while India ranks the lowest with 1%. When it comes to China, in 2016, Beijing ranked no.1 in divorce rate with 39%. Also, the rate in first-class cities in higher than that in second and third class cities. Except the cultural factors, one of the reasons, as the writer estimates, rests on strengthened selectivity and reduced reliability, because the more developed an area is, the stronger the economic independence of individuals. In developed coastal cities at home, suppliers have more resources to choose from so that the time for maintaining relations will be shorter relatively. However, in terms of several small countries or areas like Japan, Taiwan, Korea and Hong Kong, the time for suppliers continuing relations with customers appears to be obviously longer for the reason that selectivity decreases in local area due to specific limitations. In actual supplier management, the new substituted suppliers always enter the market with another suppliers exiting gradually, just like the shape below. ( Supplier Y may appear at later stage).

关系的退化并不总是发生在稳定期后的第四阶段,实际上,在任何一阶段关系都可能退化。引起关系退化的可能原因很多,如一方或双方经历了一些不满意、需求发生变化等。

Recession in relations now always take place at the fourth stage after stabilization. In reality, relations can degenerate at any stage. There are many a reason giving rise to recessions, say, one party or both parties experienced dissatisfaction or changes in needs.

这个时期的主要特征有:

交易量回落,利润下降;一方或双方正在考虑结束关系甚至物色候选关系伙伴(供应商或客户);开始交流结束关系的意图等。当客户与供应商业务交易量逐渐下降或急剧下降,客户自身的同一产品系列的总采购额并未下降时,说明客户对于供应商而言已进入衰退期,或者说有意向退出供应商。

In this period, the main features include:

Transaction amount falls back and profits reduce; one party or both start to consider ending relationship or even looking for alternative partners (suppliers or customers); the intention of initiating to discuss about ending relations, etc. When the transaction amount between customers and suppliers is decreasing gradually or rapidly yet the customers’ total purchase amount of the same product line does not decrease, the customers enters recession period, or intend to exit.

此时,供应商有两种选择,一种是加大对客户的投入,重新恢复与客户的关系,进行客户关系的二次开发;This time, suppliers have two choices: one is to increase the input to customers to recover and re-develop relations with customers.

另一种做法便是不再做过多的投入,渐渐放弃这些客户。供应商两种不同做法自然就会有不同的投入产出效益。当供应商的客户不再与供应商发生业务关系,且供应商与客户之间的债权债务关系已经理清时,意味客户生命周期的完全终止,此时供应商有少许成本支出而无收益。这是比较理想的退出方式,但实践中这个阶段通常会发生债务纠纷的情形,如同以离婚收场的婚姻八成会闹的不愉快一样,在此不再细述。

The other one is not to make too much input anymore and give up these customers step by step. Different methods will definitely generate different output effects. When customers do not have business relations with suppliers anymore, and moreover, the suppliers have already cleared the credit and debt relations, the customer life cycle is terminated completely. At this time, suppliers have little expense while no benefits, this is the ideal way of exit. Nevertheless, in practice, debt disputes always take place at this stage, just like unpleasant marriage with divorce. Here we do not describe in detail.

供应商全周期管理是端到端,摇篮到坟墓式的以透明,结构化,整合性的方式在管理供应商。

Supplier Lifecycle Management is an end-to-end, cradle to grave approach to managing suppliers in a transparent, structured and integrated manner (Smith, 2012)。

以供应商全周期来看待并管理供应商会有如下的好处Viewing and managing suppliers from supplier life cycle will bring about following benefits;

-增强全局观 Enhance 360°supplier visibility

更好的明白自身的阶段和处境,从而采取相应的管理对策来规范和优化采购方内部的流程,以及合理的发展和管理供应商。它也有助于采购方内部的相关人员了解并参与到公司各阶段战略的制定和实施中来以更快的统一战线,减少沟通中的分歧。

It will help understand the conditions and positions of themselves so that suppliers can adopt management strategies accordingly to regulate and optimize the internal process of buyers and develop and manage suppliers reasonably. It also helps relevant personnel of internal purchasers to understand and join in formulation and execution of strategies in different phases of companies in order to unit front more quickly and reduce divergence in communication.

-降低过程成本Decrease the process cost

前期供应商选择及准入阶段客户也是需要花费用的,这不仅仅指行政费用来收集,验证,存储,和管理供应商的资料,而通过有效的选择,管理及合同的签署约束,很多时候会产生快速的收益和回报,同时也有助于改善前期的行政人员,供应商及客户的效率。

Customers bare the expense in Supplier Selection and Supplier On-boarding. It not only suggests that administrative expense be used to collect, verify, save and manage suppliers’ material, but also indicates that effective selection, management and contract-signing will generate quick benefits and returns more often than not. In addition, it is conductive to improving administrative personnel at earlier stage and efficiency of suppliers and customers.

-延长生命周期中高利润期Prolong the high-profit period in life cycle

对流程的统一和快速实施有助于采购方和供应商尽快进入供应商绩效管理阶段,同时通过生命周期的前面阶段来合理控制和降低后续的风险,供应商绩效管理阶段的前期到中期是整个生命周期中利润相对来讲最高的环节,因此对这个阶段的延长将给双方组织带来可观的收益。

The unification and rapid implementation contributes to the rapid entry of purchasers and suppliers into supplier performance management, reasonably controlling and reducing risks afterwards via the earlier stage of life cycle. As supplier performance management results in relatively most profits from the early to middles stage of the whole life cycle, the extension of this period will produce considerable revenues for both organizations.

-最大化采购方利润Maximize the purchaser profit

从战略采购的角度而言,合适的供应商选择,详细的采购数据分析,合理的订单分配,精巧的供应商谈判,结合供应商改善,产品改良,制造和交付流程优化,将为采购方创造显著的节约和收益,但这依赖于采购方整台“采购机器”的良好运作,各环节的默契配合,而供应商全周期管理的概念起到了战略指引的作业。

From the aspect of procurement strategy, appropriate selection of suppliers, detailed analysis of procurement data, reasonable allocation of orders, exquisite supplier negotiations, improvement of quality, optimization of manufacturing and delivery process will create remarkable economic thrift and revenues. However, it depends on good operation of the whole “procurement machine” of purchasers and perfect coordination. The concept of supplier life cycle management, therefore, is conducive to directing strategies.

-降低采购风险Reduce procurement risks

采购风险无处不在,但供应商全周期管理让人在风险发生之前采取适当的措施去控制,例如清晰的规格要求减少质量纠纷,规范的合同要求推动供应商分担并降低各类交付中断,质保,以及设计和技术风险,批量交付阶段的延期风险在供应商准入阶段的小批试产中去验证,在供应商退化阶段提前准备新供应商的进入以缩短重叠期,甚至在退出供应商之前准备详细的退出计划,以最小化自身的损失。

Procurement risks seem to be everywhere but the supplier life cycle management enables people to take applicable actions to control the risks before they take place, such as distinct standard requirement to reduce the quality dispute, standard contract requirements to motivate suppliers to share and reduce the risks in delivery, guarantee, design and technology. It also helps examine the extension risk which happens in batch delivery in small-batch trial production at supplier on-boarding, prepare for entry of new suppliers in advance at recession to shorten the overlapping period, or even prepare a detailed exit plan before retreating from suppliers to minimize the personal lost as possible.

供应商全周期管理是一个真正意义上综合和整合供应商数据,信息以及管理的方法,并大力促使在整个从管理合规,到细致的采购数据分析,以及从关键战略供应商中获取更多利益等采购行动和活动中获得显著收益A truly holistic and integrated approach to supplier data, information and management is a huge enabler to achieving benefits across a whole range of procurement actions and activities, from managing compliance, to digging into deeper spend analytics, or getting more out of key strategic suppliers.

GREAT ACKNOWLEDGMENT GIVEN TO MS. ZIZHU WANG (AKIKO) FROM GUANGDONG UNIVERSITY OF FOREIGN STUDIES FOR TRANSLATION.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023