Views: 452

众所周知,各家主机厂OEM 都有自己的CSR (Customer Specific Requirement), 范围从体系,技术规范到生产过程不等,汽车链上制造商需要评估并确保符合。

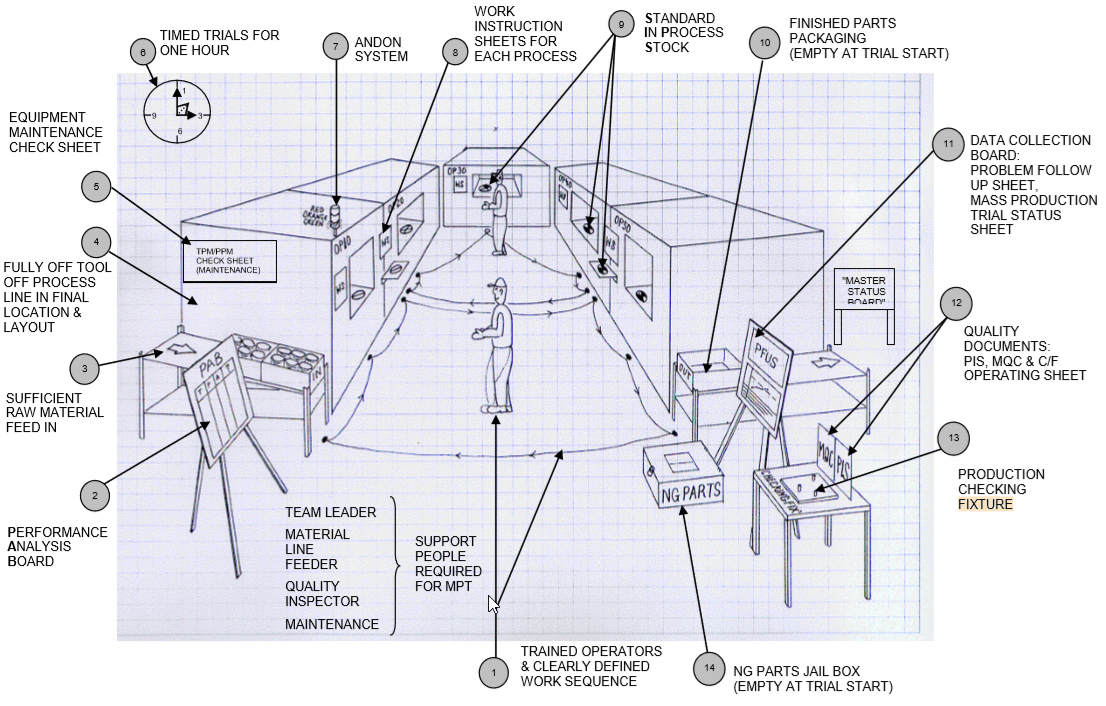

近日笔者见到丰田的供应商生产准备手册(TOYOTA SUPPLIER PRODUCTION PREPARATION MANUAL)2012 版第20章节试产管理里除了介绍不同试生产的目的,

目标以及所需要使用和报告的表格之外,甚至详细到了产线的布局草图,清晰,简单,明了,被称为“丰田生产单元要求”。

笔者将标注的项目也解释如下:

- Trained Operators For MPT one shift of production operators are to be trained, for EMPT all members involved in part production (direct and indirect) are to be trained. All training is to be completed prior to the trial, as stated on the training matrix (i.e. STAC) so that they are able to achieve the required output at the required quality level. The processes and operations they will perform must be clearly defined, documented and visible (i.e. standardised work). 一个生产班次里面的所有员工都需要被培训,所有的培训需要在市产前完成,并在培训矩阵图里面标识出来,以便他们可以达到所需要的产出以及要求的质量。他们所操作的工序需要被清楚的定义,文件化和可视化,比如作业指导书。

2. Performance Analysis Board (PAB) This is used to monitor and record the output during the trial and required from MPT onwards. The Supplier must ensure this is available on the line and used to record the trial output versus target <APPENDIX 20-B>. 产出分析表需要被用来监控,并记录所有试产阶段的产出,供应商必须确保它们在产线,并用来记录试产的产出以及目标值。

3. Raw Material Feed For raw material and component parts feed, the production racking and/or conveyors must be positioned in the line with sufficient quantities of parts, from MPT onwards. The method of material / parts feed should simulate the production condition. 原材料和零部件的供应,以及生产的存储架和传送带必须到位,并且包含有足够数量的部件,所有的试产都如此。材料和零部件的供应方法必须要模拟正式的生产条件。

4. Line Condition For all parts the minimum requirement is fully off production tool and process, with the line in the final layout and location. From the 3rd Toyota Production Trial (e.g. MPT-A, MPT-W, 2K) no changes to the process will be accepted by Toyota until three months after SOP. (Refer to SQAM Section 20 – Process Change Request). If a change after 1A is necessary, then at a minimum the Supplier should discuss this with the SPM engineer. 生产线的最低要求是完全与最终的布局和位置一致,从第三次试生产开始到量产之后三个月,工序不允许有变动,除非得到丰田的批准。参考供应商手册第20章节过程变动申请,如果从第一次试产之后,有必要作出变动,需要至少有和丰田工程师的讨论。

5. Equipment Maintenance The Supplier must ensure that the maintenance system for the line is implemented for the 3rd Production Trial, (e.g. MPT-A, MPT-W, 2K). Toyota would like to understand the daily checks, Total Preventative Maintenance (TPM), that are performed and how they are recorded. 供应商需要确保从第三次试生产开始,保养系统需要有建立。丰田需要知道每日检查,以及全面预防性保养,有实施并且是如何记录的。

6. Timed Trials For all trials, the Supplier must ensure that the duration of each trial is recorded with a clear start and finish time. 分时段的试产,供应商需要确保每一次试产的间隔时长有起始点和结束时间记录。

7. Escalation or Andon System For all off-process trials the operator should have the ability to escalate concerns. Toyota wish to understand the method within the Supplier that allows the operator to call for help when there is a concern, and how concerns are escalated within the company. 暗灯系统升级,对于所有非正式的试产,员工需要有能力升级问题。丰田希望知道在供应商内部员工是如何获得帮助来升级,以及升级是如何进行的。

8. Work Instructions & Quality Standards From MPT, each process should display the work instructions and quality standards (including boundary samples). It is then clear if the operators are working to the defined standard. 作业指导书和检验标准,从试产开始,每一道工序应该清晰地展示作业指导书以及质量标准,包含限度样品。如此就很清晰,员工是否有按定义的标准作业。

9. Standard In Process Stock (SIPS) This is a term used within Toyota to describe the number of partially processed components / sub-assemblies required in the line to ensure that finished parts can be produced when the trial starts. The supplier should ensure the standard in process stock is in place for all off process trials. 工序内库存标准,这是丰田内部的叫法,用来描述事先加工的半成品和半组件,这些确保当试生产开始的时候,成品可以被加工,供应商需要确保这些库存有就位,当试产开始的时候。

10. Finished Parts Packaging The final production packaging should be available at the end of line. This must be empty at the trial start to allow the quantity of produced parts to be recorded at the end of the trial. If production packaging is not available a suitable temporary packaging should be used. 成品包装,成品包装需要在线尾,当试产开始的时候,他们必须是空的,如此生产的数量,才能在试产结束时准确的被记录。如果没有生产包材,那么一个合适的临时包装方式需要被采用。

11. Data Collection Board A data collection board is required for all trials this should contain a Problem Follow Up sheet to record trial concerns as they are found and the Mass Production Trial Status Sheet, to record the result of the trial graphically. These can be taken from the Visual Control Centre. The Supplier must ensure that a review is held with the operators at the end of the trial. This allows the operators to raise any concerns that may exist with the equipment / fixtures, etc. 数据采集板,所有的生产需要有个数据采集板,来记录市场状态表上的试产阶段的问题,并以图表的形式来展示,这些表可以从可视化控制中心获得,供应商需要确保在试产结束的时候和作业员一起来评审,这有助于允许员工发表他们的意见和建议,而这些问题有可能来自于设备和夹具等等中。

12. Quality Documents For all trials the Toyota quality documents must be available on the line, (e.g. PIS, MQC) together with clear instructions of how to use the checking fixture (if applicable). 所有试产相关的丰田质量文件需要在产线,以及有清楚的指引来指导员工如何使用检具。

13. Production Checking Fixture For all trials the production checking fixture must be available at the line as with work instructions, to allow the quality of the finished parts to be checked, 所有试产相关的生产检具具需要在产线和作业指导书等等一起,允许最终的产品被检验。

14. NG Parts Container This must be empty at the trial start to allow the quantity of NG parts from the trial to be recorded. 不合格品容器,需要确保在试产开始的时候他们是空的,以便所有试产的不合格品有被记录。

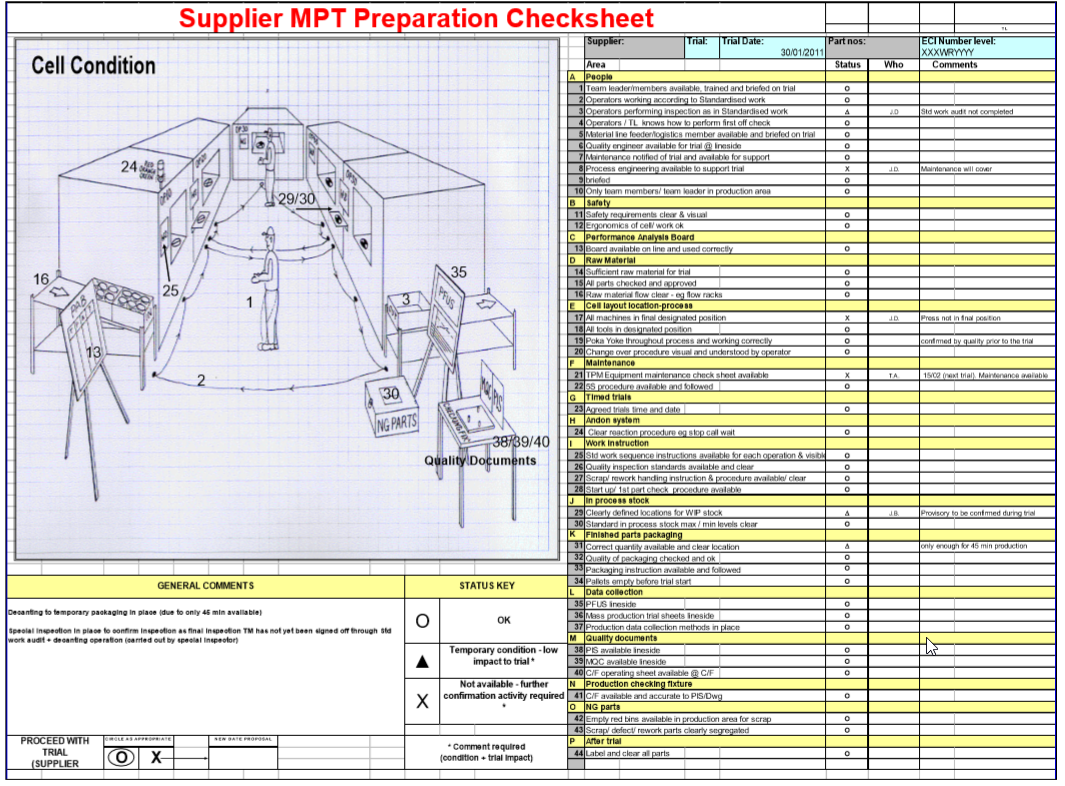

丰田也提供了一份试产前检查表,用来核对准备工作,不仅如此,也提供了一份量产前检查表(第26章节 – 2012版),用来指导供应商自查或者是丰田工程师到现场核对准备工作。

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023