Views: 419

以下是一个供应商的原文略加删减,其主要内容是对采购方中国区办公室就所采购的产品-抽屉拉手所执行的验货外观检验标准有不同观点。这是一家西班牙贸易公司,起初采购方所在欧洲总部直接向其采购后再在欧洲市场销售,后期因为采购方在中国所设的采购办公室日益强大,因此将订单流程进行改革。采购方欧洲总部下单给其采购办公室,其中国采购办公室再下单给供应商西班牙销售组,其西班牙销售组再进行内部协调后交由其香港公司下订单给最终生产商并跟踪产品的生产及交付等活动。采购方中国区采购办公室也了解供应商的合作工厂是哪些,以及具体的联系人,但是出于其同欧洲总部长期以及成熟的业务关系,因此不参与供应商具体的生产厂选择。

Below is a pruned piece of correspondence by a supplier to the Chinese purchasing office of of a German customer, reading its trouble from the discrepancy of requirements between the Chinese representative office and its headquater on product appearance. The supplier is located in Spain. At first, the purchaser European headquarter bought from it directly and sell in the European market. As the purchasing office of the purchaser got increasingly powerful, it reformed the process of placing orders. The headquarter places an order to the office which then send the order to the Spanish sales group of the supplier. After an internal coordination, the sales group places an order to the final manufacturer via its Hongkong branch and keep track of production and delivery. The Chinese purchasing office knows about the supplier’s partner factories and their contact persons. But it does not intervene the selection of manufacturers as the Spanish company has long and good relationship with German customer

“We have noticed an increasement of "QC rejected" issues. This is not good for all of us, we would like to find solutions to lower this issue and work more smoothly.

The AQL level used on the inspections is very strict but here few discussions can be done. Main issue here is the grade level of our factories. We have a lot of problems the reach the Quality Level 5 asked from your side.

We were never informed that the level was raised from 3 to 5, this is a very strict regulation which will need a lot of energy and time to for fill. We now are forced to make much more production to have a level 5 quality, and these not accepted articles are waste.

5000 kelvin inspection environment, this for us is not possible, we don't have the right installations to do this test.

Waste material, we need to produce more to have 0 defects quality.

Delivery times, if the order is rejected delivery dates are not completed.

Of course we will do our best to reach this level but it will not be easy, our commercial gain will be reduced to almost 0 because of the waste products we have to make.

Delivery dates given are respected but due to the high quality level asked, delays may appear (because of rejections). Again we will do all possible to reduce these delays to a minimum, and we will work together with the factories to go as smooth as possible.”

其实供应商在投诉采购方欧洲总部和中国办公室采用的是不同的书面外观质量标准,以及两者间实际实施时候检验员在操作上面的差异给其带来的困扰,以及给双方业务带来的潜在障碍和风险。因为作为“受害者”,他们最清楚自己的生产改变了什么,以前的客户对品质反馈如何,现在订单流程改变后客户对品质反馈又怎么样。

In fact the supplier was complaining about the different appearance quality criteria adopted by the purchaser’s headquarter and its office in China, which troubled inspectors in practice and brought potential obstacles and risks to the business. As the victim, the supplier knows clearly how its production has been changed, and what customers’ feedback on quality was and what it is under a changed order-placing process.

究其原因,接触过外观标准的人或许深有体会,参与鉴别的人越多,标准越难定义清楚,实施起来就越不容易把握。

As for the reason—people who once touched upon the appearance criterion may have something to say—the more the people are engaged in making criterion, the harder a criterion will be settled and the harder the practice will be.

在案例中采购方为了统一全球的质量标准,在原来没有统一的书面标准的基础上开始拟定外观质量标准,并按标准将产品质量分为三六九等,以满足不同客户和市场的需求,同时也便于供应商生产加工。由产品工程师开始通知各供应商,并由产品部门连同质量部门对各相关部门和人员开展培训。

In the case, in order to establish a globally unified quality criterion and facilitate the supplier’s production, the purchaser begins to draft appearance criterion for the first time and grades the products according to their quality to satisfy different customers and markets. Suppliers are informed by the product engineer and training is given to all departments concerned by the product and the quality department.

在实际培训的过程中,一定会发现有新出现的缺陷或者现象不在标准的定义里,或者严格按标准去执行的话,又不一定符合实际的生产情况,导致生产和交期困难。这种脱离实际的标准造成“跳跃式过渡”,不是一种“平稳过渡”,从而会失去实施的意义。因为质量的改进是渐进式的,而不是爆发式的。长期稳定供应了很多年的产品不会因为 “一纸文书”而一夜之间改变产品的质量水准。

In training, there may arise some new defects or phenomena that are not covered in the criterion, or some criterion items proved to be contradictory to the practical production which results in difficulty in production and delivery. Since quality improvement is gradual rather than explosive—products that remains the same for many years cannot change its quality due to a piece of paper in a short time— this deviating-from-practice criterion, a kind of leaping transition rather than a steady one, loses its practical significance.

质量从来不是某一个人或者某一个部门说了算,一定是要大家的共同认同,否则分歧和矛盾一定会在某个时期后爆发。确保品质平稳提升,前提就是要培训并校准所有参与人员的鉴定能力。因为这个时候每个鉴别者其实就是一个测量工具,每个人心中各有“一杆秤”,它既不同于定量型数据,也不同于定性型数据,可以采用常规的校准或者量具的重复性-再现性分析来确认达标与否。

Quality criterion cannot be determined only by one person or one department, which comes into being as a consensus to avoid differences and contradictions that may otherwise erupt Sonner or later. A premise to ensure a steady improvement in quality is to train all the people concerned and calibrate their identifying ability. Inspectors can be regarded as a measurement tool and each person has their own scale, which is neither sheerly quantitative nor sheerly qualitive and thus cannot be calibrated in the common way conventionally or judged by GR&R.

真假美猴王,孙悟空火眼金睛,一眼就能看出来谁是妖怪变的,但终归也有失手的时候,就像妖怪骗走其辛苦得来的“芭蕉扇”时。做不到百分百准确,“十拿九稳”应该也不错了,GR&R 也没说一定要为零才证明测试系统是可靠的,培训也应如此,不必期望所有的测试者个个测试结果都“击中靶心”,更何况在实际工作中标准也可能会因为客户和市场的“苛求”而“水涨船高”。就培训而言,笔者的经验是应该理论结合实际,理论部分先培训,然后结合实物鉴定。无论何种培训都应该有考核,用当下流行的话说,没有考核的培训就如同耍流氓。

Sun Wukong, a fictitious character in an ancient Chinese novel, is able to tell human-like monsters apart at a glance with his fiery golden eyes that penetrates all. Powerful as he is, he once has his plantain fan which he has procured with great efforts stolen by monsters, proving the saying that even Humor sometimes nods. If we cannot achieve 100% correction, 90% is compromisingly ideal; the result of GR&R should not be 0 to demonstrate the reliability of tests. So it is the same with training in which all trainees should not be required to produce perfect outcomes. Let alone the criterion may be forced to rise in practice by customers and the market. According to the author’s experience, the training should combine theory and practice, first training on theory and then on practice. Besides, trainings should be coupled with examinations. To conclude it in a currently popular style, training without examination is being a rogue.

理论培训和考核容易理解,常规的做法是将标准内容设置为闭卷或开卷的考题供学员考试评分,达到一定级别才算合格。对于实际运用的考核,就需要结合鉴定者的能力多下一些功夫了,因为毕竟不可能每次发现瑕疵就查阅标准。笔者的经验是以下的步骤可供参考。

The theoretical training and examination are easy to understand. The conventional practice is to test and grade trainees concerning the training content whether in an open- or close-book form, and those who reach a certain grade pass the examination. The practical examination requires more efforts to test out trainees’ true ability because a qualified inspector should not look up the criterion every time a defect is spotted. The author thinks the following steps can serve as reference.

- 按书面标准要求准备检验环境,比如投影仪,秒表,光源箱,眼镜,外观检验卡(见http://supplierlifecycle.com/aesthetic-quality/),卷尺,纯棉手套,铺有防擦伤布检查台,不良品容器箱等。因此通常各公司规定的要求里少不了每个面或产品的观察时间以及观察距离,同时充足的光线和色温也会影响鉴别结果。设计并准备好记录用的纸张和笔,箭头标签纸。Prepare inspection environment as required, such as projector, stopwatch, light box, glasses, appearance inspection card (see in http://supplierlifecycle.com/aesthetic-quality/), tape measure, cotton gloves, check stand with anti-abrasion cloth, defective products containers, etc. Usually companies also stipulate the inspection time and distance for each product. Meanwhile, the degree of light and color temperature can have an effect on the results. Design and prepare note sheets, pens and arrow marking labels .

- 对常见的产品类型从批量生产的产品中各抽取10个样品,当然可以更多,也尽量覆盖标准中的所有缺陷现象为佳。其中有好坏产品数量不一,并标号编号,以便登记不同的鉴定者的检查结果。切勿标示缺陷在供测试的样品上,因为目的就是考验检查者发现瑕疵的能力。Select ten or more samples of a product in one mass production, better to cover all the defects listed in the criterion. Good and defective products differ in number, and they are numbered so as to make records easier. Do not make a mark on the defective products that tells them apart for the examinees are supposed to do the job to prove their defect-discovering ability.

- 邀请一个经核准的经验丰富的产品工程师或质量代表作为“考官”先给各个样品评级,并记录下评定结果以及瑕疵现象。Invite a checked experienced product engineer or quality representative as the examiner who first grades each sample and record the inspecting results and defects.

- 请各鉴定者随机检查所有的样品,同时也请鉴定者不仅仅只是观察并评价外观的接受否,而且需要记录有“缺陷”时所观察到的瑕疵,因为经常会发现评价者判“不可接受”不是因为其发现了该观察到的缺陷,而是发现了其他不需要特别留意的不在考核范围的其他瑕疵。如果检查时有疑问,先自主查阅标准。如果可行,也可以请各鉴定者多随机鉴别一次,以检查其“重复性”鉴别的能力。Ask each inspector to check all the samples randomly, and record not only a product’s appearance is acceptable or not, but also the specific defects if a product is defined to be defective. Chances are that a product sample is identified as unacceptable by an inspector due to pointless details not covered in the criterion. Inspectors should refer to the criterion first when questions arise in the process. If possible, they can be allowed for one more identifying chance to test out their repeatability.

- 登记所有鉴定者的检查结果,打印或者投影出来给每位鉴定者,比较每次同“考官”的一致性,并最终汇总总的一致性比例,并同预先设定的目标值对比,满足即为合格,否则不合格,重新准备考核。Register the inspection results of all the inspectors. Print it or project it on the screen so that every one can see it. Compare the consistency between each one’s record and that of the examiner. Finally summarize a general consistency rate and compare it with the pre-determined target value. Those who meet the target value pass the examination while those who fail will be re-examined.

- 作为最后一个环节,也是培训中经常容易忽略的环节,就是反馈结果。考完了,得到了最后评分,但是不晓得错在哪里。这个时候需要重新将样品按序排好,按每一个同大家回顾各自的打分以及备注的瑕疵,将最终确认的瑕疵范围用笔圈起来,防止被人为有意无意的扩大,其次用箭头标签指示出来,在箭头标签上注明人员,日期,瑕疵内容,以及可接受的程度。作为今后的再次培训,可以将样品封存保留。The last step is feedback, which is the step most easily to be overlooked in training. It is possible that inspectors get the final score after the examination, not knowing where their mistakes are. In this case, rearrange the samples in number,go through all the defects and each inspector’s judgement, as well as their score, finally circle and mark the defects which are agreed between examiner and inspectors to ensure the defects are clearly being understood and only limited to in case in future extra defects are made. Later indicate them with arrow labels on which the inspector’s name, date, defects and acceptance degree are listed. The samples can be preserved for later training.

- 为确保人员一直拥有稳定的鉴定能力,还应该结合实际工作中的表现定期或者不定期再次参照以上样品重新培训,因为人的视觉容易形成一种审美疲劳,看的时间久了,鉴别能力就容易下降,对瑕疵熟视无睹。To ensure that they keep their identifying ability stable, new trainings of this kind should be held regularly or irregularly on the basis of the inspectors’ performance in work. It is because inspectors may be less alert to defects after a period of time due to aesthetic fatigue which weakens the identifying ability.

如果没有经过以上或者类似的培训并反复校准,很难说大家对瑕疵的鉴别能力是一致的。如果在生产检验环节随机挑两位检验员并按以上的方法进行到第5步,你会惊奇的发现,工作了很久的熟练工其实只是动作上的熟练工,检验结果其实并不准确,熟练并不与准确相等。就像很多人写了多少年的汉字,其实你发现依旧很潦草,一笔一划难以识别,同时很可能笔画的顺序也是错的。It is hard to claim that inspectors have equal ability in identifying defects without being repeatedly calibrated by the above or similar trainings. Randomly choose two inspectors go through the above steps until step 5, and you will surprisingly find that although they are skilled in motion, the results are not so correct—being skilled does not equal to being correct. It is the same with handwriting. Some are skilled at writing but not good at it. They just scrabble in wrong stroke orders.

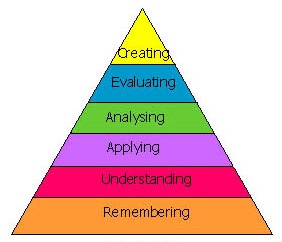

布卢姆(Bloom’s Taxonomy)将学习的认知分为6个阶段:知道(Remembering)、理解 (Understanding)、运用 (Applying)、分析 (Analysing)、评价 (Evaluating)及创新 (Creating)。 According to Bloom’s Taxonomy, the study recognition process consists of 6 stages: remembering, understanding, applying, analysing, evaluating and creating.

知道:对先前学习过的知识材料的回忆,包括具体事实、方法、过程、理论等的回忆。Retrieving, recognizing, and recalling relevant knowledge from long-term memory.

理解:把握知识材料意义的能力。Constructing meaning from oral, written, and graphic messages through interpreting, exemplifying, classifying, summarizing, inferring, comparing, and explaining.

运用:把学到的知识应用于新的情境。Carrying out or using a procedure through executing, or implementing.

分析:把复杂的整体材料分解为组成部分,并理解各部分之间的联系的能力。Breaking material into constituent parts, determining how the parts relate to one another and to an overall structure or purpose through differentiating, organizing, and attributing.

评价:对材料(如论文、小说、诗歌、研究报告等)做价值判断的能力。Making judgments based on criteria and standards through checking and critiquing.

创新: 将所有的元素形成一个相互关联的整体:通过创造,计划及加工,重新排列元素形成一个新的样式或结构Putting elements together to form a coherent or functional whole; reorganizing elements into a new pattern or structure through generating, planning, or producing.

作为外观检验员,将标准的理解运用在实际的工作当中就已经够了,但是如果对标准的掌握能力没有经过校准,那光有熟练也是徒劳。It is enough for an appearance inspector to put his or her understanding of criterion into work. But the inspector will work in vain before the understanding of criterion is calibrated.

Acknowledge given to translator Ms. Wang Qian (Claire) from Guangdong University of Foreign Studies

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023