Views: 2471

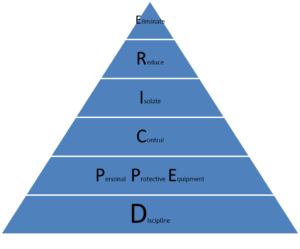

There is Hierarchy of Risk Controls – ERICPD in Safety management.

E means Eliminate. Consider whether the substance could be altered or substituted such that it no longer presents a hazard. If the risk is clamping hands when close the door and you remove the door then it's called elimination of the risk. Change the rotation system of machine to flat moving operation is another typical example for avoiding pinching hair. Advance the manual operation steps to be fully automatic will eliminate the risk source as well. In reality nowadays the electronic locks especially fingerprint type become more and more popular and one reason is that you do not need to worry about forgetting keys anymore – the risk of losing key is eliminated.

E means Eliminate. Consider whether the substance could be altered or substituted such that it no longer presents a hazard. If the risk is clamping hands when close the door and you remove the door then it's called elimination of the risk. Change the rotation system of machine to flat moving operation is another typical example for avoiding pinching hair. Advance the manual operation steps to be fully automatic will eliminate the risk source as well. In reality nowadays the electronic locks especially fingerprint type become more and more popular and one reason is that you do not need to worry about forgetting keys anymore – the risk of losing key is eliminated.

R stands for Reduce. Consider reducing the frequency, degree or inventory of the substance such that the risks are reduced. Reduction in risk factors will relieve problem severity. Toy fan speed is limited to avoid injury of children. Electrical motor speed (max.20km/hour) is not set to gas motor as many drivers are seniors. The shoes shelf at kindergarten is designed to be much lower than normal ones.

In many industrial or consuming applications the voltage degree is designed to be low such as decorative flicking LEDs strips. Soft protectors are used for sharp and hard corners or edges, and round pillars are also broadly adapted.

In many industrial or consuming applications the voltage degree is designed to be low such as decorative flicking LEDs strips. Soft protectors are used for sharp and hard corners or edges, and round pillars are also broadly adapted.

In daily life I personally have some bad cases for slippery shoes which resulted in falling down – the bottom of shoes are too smooth and cannot grasp the floor. Furthermore I noticed that in the children caring center there is slot on the door to minimize the possibility of crimping babies' hands, and knob locks are also used instead of lever handles to ensure difficulty of children to open or close the door.

From design pespective, roundness are specified to ensure products have smooth surface and correct process to make it. Cutting hair shorter is another way to reduce the risk of pinching hair. I was told the top failures of hair dryers are long hair entering the motor of machine and burning down the motor. Think of the reported injury cases from children playing long and thin thread. Is not it very similar?

I represents Isolate. making safe by separating the hazard from the individual through physical isolations or zoning. To separate the risk factors away from operators, such as for vibration machine like parts feeding device,there is always noise disturbing people and one good practice is to put the device in a closed and transparent cabinet. Placing a matt over the oily floor or stairs is another example to isolate the slipping factor. Covering the running wheels is a typical way to isolate the risk of clamping hands, hair and cloths.

C is Control. Enacting managerial arrangements to prevent exposure to the hazard. It is not enough to only give staffs the sufficient and correct Personal Protective Equipment (PPE) but missing control, however it is common in practice. Controls such as below are important and useful: 1.Set up a procedure of how to manage the PPEs, usage, monitoring and feedback system. If you just give caps to female workers operating rotating machines but actually they do not use them, will it work? 2.Establish clear working instructions and visual indication labels for risky areas and stations. It always not easy to develop good working instructions or Standard Operation Pictures. 3.Train staff, demonstrate and encourage good examples. Records with signatures should be clearly kept to evaluate next cycle retraining, and they will also support you to prove your organization has good training system. 4.Develope a monitoring and feedback cycle process. Do you allow or even encourage your people to work overtime and how do you manage those issues? Is there an clear escalation process to manage overtime as many cases happen because of this. Do you share good practices, experiences and results to staff?

P equals Personal Protective Equipment (PPE). Allow exposure but protect the individual with Personal Protective Equipment (PPE). It seems more and more Chinese and south Asian factories now provide PPE to operators. However it's still common that not all the PPE are in good quality or they are wrongly used, either not all persons exposed to risk are given to, such as visitors.

D stands for Discipline. Reliance on operator training to minimize the risks. This is the worst situation as operators are just requested to be careful when performing tasks and they take their own risk to be safe. In case accidents occur, they may be punished but limited preventive actions are taken to avoid reoccurrence.

So now do you have any idea about process of power coating which is a very common surface treatment process? In "E" level, you may think about cancel the surface treatment or replace to be non-hazardous materials. In "R" level, you may consider safer substitutes or semi-automatic sprayer to reduce exposure frequency. In "I" level, the operation could be done in separate room. In "C" level, you may switch the operators to be more faster and ensure they stay in the working environment less time, and physically incapable staff are not allowed to work for that position. In "P" level, sufficient training and PPE will be supplied. In last "D" level, possible you will see the workers are not so willing to work there.

In general ERI are more like Engineering controls and CPD are administrational approaches. The risk control pyramid helps you to think about the better approaches when you encounter some risk problems in operation and real life, as there is probably no way to eliminate all the risk but control them to minimum level.

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

Good Points!