Views: 2203

在合同篇里,笔者提到了供应商手册,并将之同员工手册相提并论。接触过不同公司人力资源部的都会有些印象,每家公司的组织架构框架都大同小异,而且凡是有基本管理制度的一定少不了员工手册,只不过每家公司在内容编撰上略有不同而已。目的都是一样,将规章制度,奖惩措施等先列出,做到事前预加引导,事后有“法”可依。

In contract part, I mentioned the supplier manual, and bracketed it with employee manuals. Anyone that once got in touch with human resource management department may be impressed that each company utilizes the seemingly similar organizational structures in spite of differences in minor points. Moreover, companies with basic management system must also possess employee manuals—they merely differ in contents from companies to companies, as their goals are the same: to list rules and regulations and measures of reward and punishment in advance, to make preliminary guidelines in advances and create criteria for operations.

供应商手册也是同理,对供应商起一个引导约束的作用。最理想的状态当然是在供应商进入系统前就签订,但是往往实际情况是不一定做得到。

Similarly, supplier manuals guide and restrict suppliers. The most ideal condition must be the contract signed before suppliers entering the business system. However, this is not always the case.

其一,可能企业在供应商管理方面比如薄弱,暂时还没有供应商手册,只是凭借熟人关系和采购订单行事。跨国采购绝大部分的小采购商也是没有供应商手册的。

First of all, it may be possible that enterprises are weak in managing suppliers so that they do not have supplier manuals temporarily. Instead, they act simply according to acquaintances and procurement orders. Most of the small foreign merchandisers do not have supplier manual either.

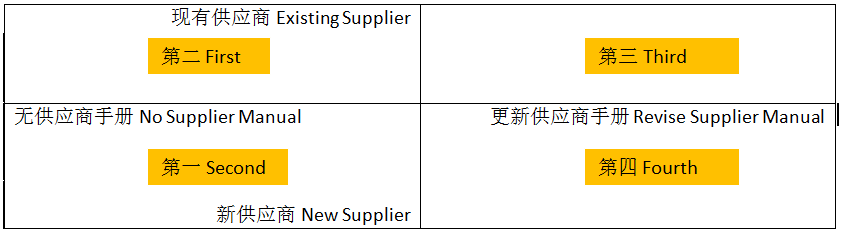

其二,如果有供应商手册,需要分开新供应商和现有供应商来看。对新供应商,可以要求所有供应商签署;而对于现有供应商,则需要视供应商所在的采购象限而定,因为供应商手册有可能是从供应商进入系统之时就因为各种原因没有签署,也有可能是供应商手册是在供应商进入系统之后才编撰的,也就是其上之一的状况。这时的供应商手册相当于是在实践的基础上编制的,同时会加上新的未来的要求,当然供应商不愿签署了,需要同现有供应商商议,针对不同的供应商有所删减和增补。

Secondly, if they have supplier manuals, enterprises need to treat new suppliers and existing suppliers differently. For new suppliers, the enterprises can require all of them to sign, while for existing suppliers, it should depend on the purchasing quadrant they belong to. It may be because supplier manual had not been signed for various reasons at the time suppliers entered the system, or it may be because that supplier manuals were compiled after suppliers entered the system— one of the conditions listed above. At this time, supplier manuals are compiled based of practices, and requirements for future are also added. Thus, suppliers appear to be unwilling to sign. Therefore, enterprises should discuss with existing suppliers and amend the contents of manuals slightly for different suppliers.

其三,最常见的现象是更新现有的供应商手册,往往因为“改朝换代”或者“时过境迁”,更换了新的组织领导人,而新的领导者带来了新的管理理念,尤其是采购方面的理念。对于新供应商而言,无妨,按新的制度执行,但是对于现有供应商,有个重要环节就是保持政策的连贯性,以及一致性。需要同以往的供应商手册反复对比,斟酌,以确保增加或删减的条款更加符合时宜;同时如果是集团公司,又需要兼顾总部的大方向,甚至直接同集团同步化,同版化。

Thirdly, the most common phenomenon is the update of existing supplier manuals. More often than not, the change of leadership or business strategy, and new leaders bring in new management philosophy, especially that in procurement. For news suppliers, the new policy shall be followed , but for existing suppliers, one of the important links is to keep the coherence and consistency of policies. Thus, they need to compare new manuals with past ones repeatedly and consider carefully to ensure the deleted or added terms are appropriate. Meanwhile, if the enterprises are group companies, they have to pay attention to the general direction of the headquarters’ as well, even can they synchronize with and copy from the group directly.

供应商手册的内容应该是采购或者供应合同的补充,就如同员工手册与员工合同是两件文书一样。从笔者观察的近30份不同组织的供应商手册来看,供应合同重点在于商务板块,而更多的组织把供应商手册的重点放在质量系统的要求和期望,是对ISO9001 和 ISO/TS16949 的内涵的具体解读和实施。

The content of supplier manuals should be the supplement of procurement or supply contract, just as the employee manual and employee contract are two documents. From my observation of nearly 30 supplier manuals from different organizations, the emphasis of supply contract lies in business and commercial areas, yet more organizations put emphasis of supplier manuals on requirement and expectation of quality system, regarding them as the detailed interpretation and implementation of ISO9001 and ISO/TS16949.

其内容框架通常如下,不同企业顺序略有调整:

The framework of the content of supplier manuals is as the following, and the sequence is varied from enterprises to enterprises:

- 概要Quality General

- 供应商评估Supplier Assessment Survey

- 高级产品质量策划Advanced Product Quality Planning

- 过程批准Process Sign-off

- 部件提交及批准Supplier Part Submission

- 产品环保指令要求 Product Non-hazardous substances

- 测量系统分析Measurement System Analysis (MSA)

- 统计过程控制Statistical Process Control

- 绩效跟踪Performance Monitoring

- 验收及退货Receiving Control

- 投诉及问题解决流程Problem Solving Documentation

- 质量评审Supplier Management Quality Review (MQR)

- 升级及围堵Escalation and Containment

- 变更管理Supplier Request For Change

- 质保Supplier Warranty

在此基础之上,已经有多种增补的趋势。

The various trend for supplement has appeared on the above basis.

第一是对整个供应链的关注(Supply Chain Collaboration),而不只是下一级供应商,因为越来越多的组织意识到要致胜,不能单凭自身和下一级供应商,而是整个供应链。

Firstly, the Supply Chain Collaboration. The focus should be paid on the whole supply chain rather than merely the sub-suppliers. Because more and more organizations became to realize that they cannot solely rely on themselves or sub-suppliers but the whole supply chain to win the competition.

第二是供应商手册里包含各类法规要求,劳动法规,环境法规,健康安全法令等等,也就是跨国企业里普遍关注的企业社会责任(Social Responsibility),因为这些要求已经变为一种终端用户选择产品的其中一个考量,同时是上游客户营销的一个推广点,它们不仅来自于政府监管,和法律条文,更加来自于客户的直接要求。

Secondly, the supplier manuals contain various laws and regulations, such as labor laws, environmental laws, health and safety laws and so on. These are also social responsibilities that multinational enterprises generally pay attention to, since these requirements have already become one of the factors that affect consumers’ selections for products and a brand proposition for upstream customers. Not only do them come from government’s regulations and laws, but they also come from direct command of customers.

第三种趋势是对产品品牌及包装(Branding and Packaging)的关注,因为好的品牌设计和维护是增值的,而好的包装设计不仅可以有效保护产品,同时可以改善物流运输环节的效率,甚至促进销售,同样也是为产品加分的。

The third trend is the focus on branding of packaging of products, because good product design and maintenance are value-added. Good packaging design, however, can both protect products effectively and improve the efficiency of logistics and transportation, even promote sales. Thus, it also adds value to products.

其次,有些组织将供应商手册也称为供应商质量手册,因此在里面没有关于商务的要求,如果增加商务的内容,比如以下等等,则称为供应商手册更为妥当。

Furthermore, supplier manuals are also known as supplier quality manuals in some organizations. Thus, requirements for business are not included. If content regarding business as followings can be included, then it is more appropriate to call them supplier manuals.

- 订货流程Order Process

- 交付流程Delivery Process

- 价格及付款Price and Payment

- 知识产权Intellectual Property

供应商手册如同ISO9001 管理质量手册,在供应商管理还没有像目前质量管理的流程如此成熟之前,它只是组织管理供应商的一个大的框架。在此之下的每个章节都应该有具体的操作流程,和工具,而这些就如同ISO9001下的作业指导书和表格表单。而因为它是一块奠基石,因此又务必要重视。

Supplier manuals just like ISO9001 quality management manuals, which act merely as big frameworks for organizing and managing suppliers before the process of supplier management becomes as mature as that of current quality management. Under this circumstance, every chapter should have its own operation process as well as tools, which act as working instructions and form under ISO9001. It is because supplier manuals are cornerstones that they should be highlighted.

在实践中供应商手册通常由质量部负责起草编制,并会同其他部门和团队一同商议审定,尤其是采购部,以确保质量,成本和交期铁三角的稳定性和制约性,同时又保证了其他部门的参与性,以降低在落实环节的抵制和阻力。而编制的页数又经常动辄几十页,因此无论是打印装订成册或是发电子版给供应商,亦或是公布于供应商网络访问端口,都难以确保供应商有认真阅读,大多只是敷衍了事。因此为确保供应商有认真理解这些手册要求,建议在关键供应商启动初期同供应商见面讲解这些要求和内容,并了解落实的难点何在,其一消除供应商误会,其二在签订前做适当的修改,其三供下次修订作参考。

In practice, it is the quality department that take the responsibility of drafting and compiling supplier manuals. They usually discuss with other departments or teams to decide on the final version, especially with the purchasing department to ensure the stability and conditionality of the iron triangle, composed of quality, cost and delivery time. Simultaneously, participation of other departments is ensured to reduce resistance and cost of implementation. In addition, there are dozens of pages involved for compilation. Thus, it is hard to ensure that suppliers have read them carefully no matter they are printed and compiled in volumes or sent to suppliers in electronic versions, or published in the suppliers’ network access ports, since most of them just give a glimpse carelessly. Thus, to ensure that suppliers have understand these requirements listed carefully, it is better to explain these requirements and content with suppliers face to face at the beginning of the startup of key suppliers and understand difficult points for implementation. Firstly, it can eliminate understandings from suppliers. Secondly, appropriate modification can be made before the agreement is signed. Thirdly, it can be the reference for modification next time.

有关供应商手册的范例,请在下载页查看。

Please check the examples for supplier manuals at the download page.

Great Acknowledge Given to Ms. Akiko Wang from Guangdong University of Foreign Studies for Translation

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023

粤ICP备2022015479号-1 All Rights Reserved © 2017-2023